Venezuelan

Aluminium Industry, C.A., CVG Venalum. In the background, the design of the

capacity expansion project for lines VI and VII. Photo and Design: CINTAL

TECHNOLOGY,

ENGINEERING, AND INTEGRATED MANAGEMENT: KEY ELEMENTS FOR PRODUCTIVE SOVEREIGNTY

BASED ON TECHNOLOGICAL SOVEREIGNTY

CONTENT

INTRODUCTION

TRAINING

AND DEVELOPMENT PROCESS AT CVG VENALUM

PLAN FOR

THE ADOPTION AND INCORPORATION OF TECHNOLOGIES INTO MODERNIZATION AND V-LINE

PROJECTS

LEARNING

THROUGH THE TECHNOLOGICAL DEVELOPMENT PROCESS: DESIGN OF THE V-350 ALUMINIUM

REDUCTION CELL

TECHNICAL

AUDITS ON THE ALUMINIUM REDUCTION TECHNOLOGY DESIGN: THE V-350 CELL

V-350:

VIRTUES AND BENEFITS

SPECIALIZED

TECHNICAL ASSISTANCE TO CVG ALUMINIUM COMPANIES AS A BYPRODUCT OF RESEARCH AND

DEVELOPMENT

TECHNICAL

ASSISTANCE TO CVG VENALUM

TECHNICAL

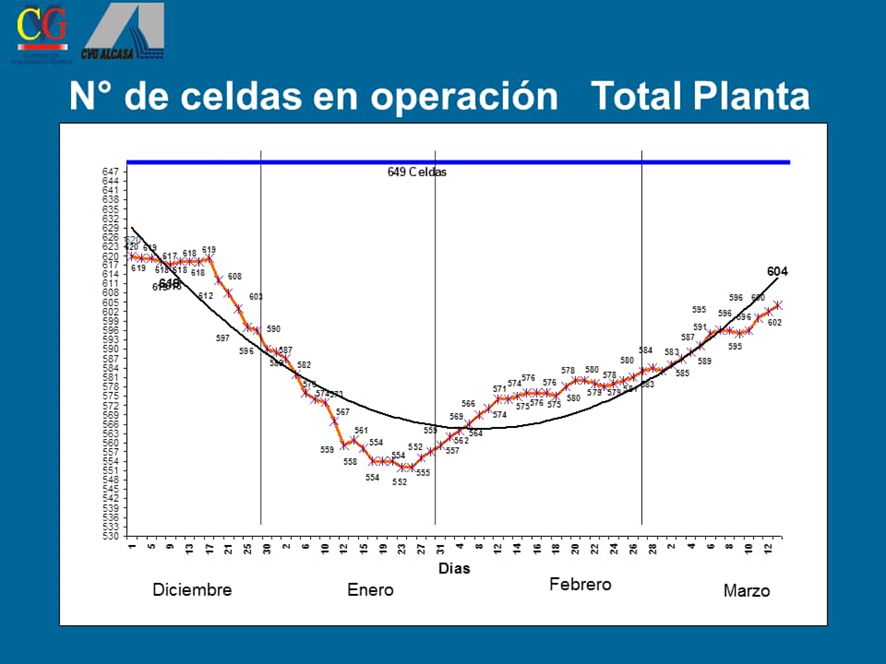

ASSISTANCE TO CVG ALCASA

TECHNICAL

ASSISTANCE TO CVG BAUXILUM

TECHNICAL

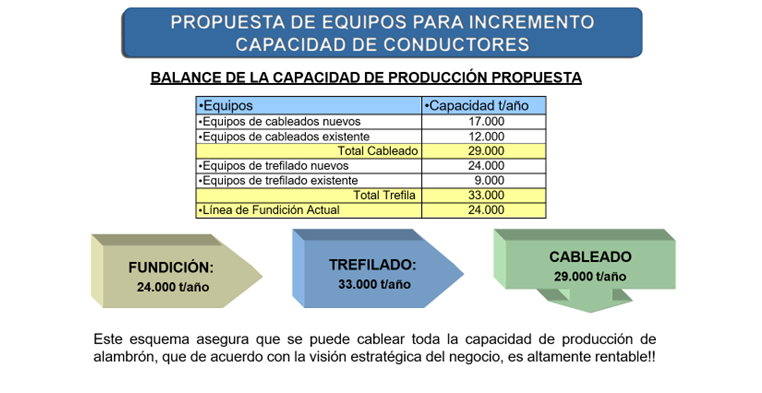

ASSISTANCE TO CVG CABELUM

TRAINING

OF RESEARCH AND DEVELOPMENT PERSONNEL AT THE MASTER'S AND DOCTORAL LEVELS

COMPREHENSIVE

AND HARMONIOUS PLANNING FOR SUSTAINABLE DEVELOPMENT

PRACTICAL

RESULTS AS PART OF THE EVOLUTIONARY PROCESS OF THE INTEGRATED ALUMINIUM INDUSTRY

EXPERIENCE

IN THE DEVELOPMENT AND MANAGEMENT OF EXPANSION PROJECTS

CONCLUSIONS

INTRODUCTION

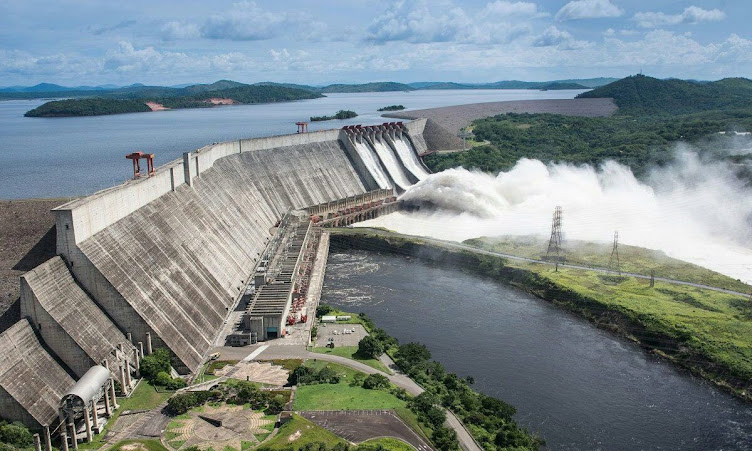

In 1975, the construction of Industria

Venezolana de Aluminio, C.A., CVG Venalum, commenced, and it began production

in 1978 with an annual output of 70,000 tons. The construction of its 4 cell

lines using Reynolds Technology, providing an installed production capacity of

280,000 tons per year, was completed by the year 1980.

After implementing enhancements to modernize

its original cells and additionally constructing the V-Line with Hydro

Aluminium Technology, from the 1990s onwards, CVG Venalum achieved an installed

production capacity of 430,000 tons per year, until the supply of electricity

was suspended in 2008.

In 1990, the V-350 cells, cutting-edge 100%

Venezuelan Technology designed by CVG Venalum engineers, began operation with a

production capacity of 2.5 tons per cell per day.

The human capital that received training

organized by Reynolds Metals Company personnel primarily came from our

educational institutions: middle-level technicians, INCE technicians, Higher

University Technicians (TSU), as well as graduates from our universities.

In the late 1970s and early 1980s, the country

started to receive a significant number of university graduates from

universities worldwide through the GRAN MARISCAL DE AYACUCHO SCHOLARSHIP

PROGRAMME.

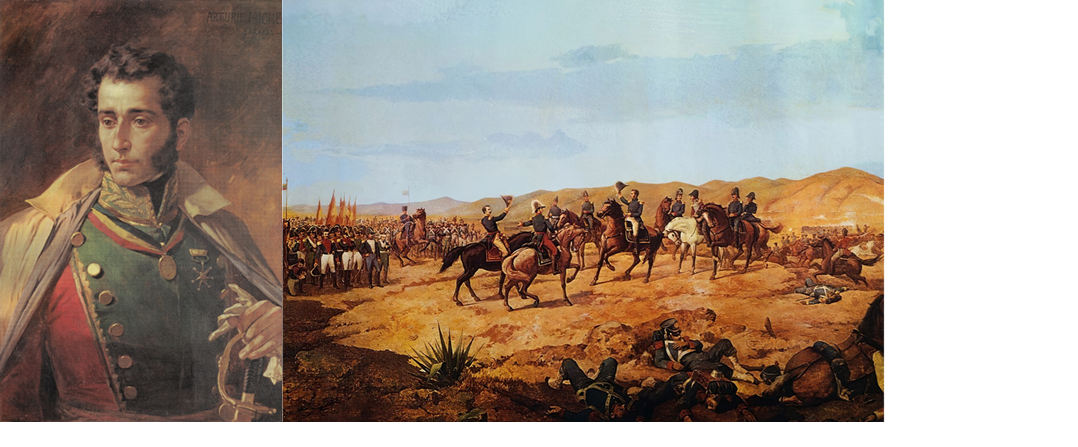

This initiative by the President of the

Republic, Carlos Andrés Pérez, began on June 4, 1974, with the issuance of

Decree No. 132, which established this programme in honor of the sesquicentennial

of the Battle of Ayacucho, allowing young Marshal Antonio José de Sucre to

complete the process of liberating Latin America.

Antonio José

de Sucre. Michelena, Arturo. 1895, Palacio Legislativo, La Paz. Batalla de

Ayacucho, óleo sobre lienzo de Martín Tovar y Tovar (1827 - 1902)

The purpose of the Gran Mariscal de Ayacucho

Scholarship Programme was aimed at the training of human resources that would

enable us, through a process of technology acquisition and assimilation, to

overcome the stages of scientific and technological dependence and definitively

join the group of autonomous and truly developed countries.

In this regard, the Gran Mariscal de Ayacucho

Scholarship Programme was created, considered a true programme of innovation and

democratization of education.

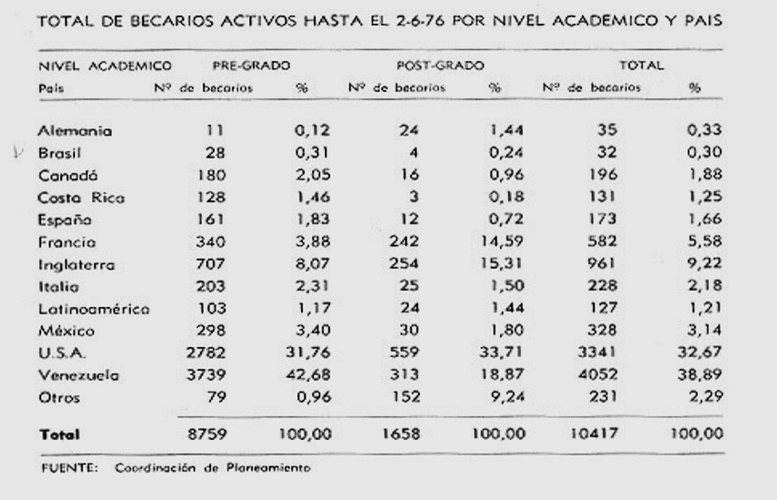

Of innovation, because Venezuela is one of the

few countries in the world that, by the year 1976, could embark on this

significant task, which would allow it to support approximately 11,000

scholarship recipients both within the country and abroad, a truly significant

number for the country's 12 million inhabitants at that time.

On democratization, because the opportunity was

given to young individuals, primarily from the country's interior and from

households with modest economic resources, both within the country and abroad.

With this, the central government demonstrated that education truly constitutes

a fundamental factor of promotion in all aspects.

A well-educated and skilled population is

essential for the achievement of a nation's economic and social well-being.

Education plays a pivotal role in providing individuals with the knowledge,

skills, and competencies necessary to effectively participate in society and

contribute to a country's economic support.

Quality education significantly enhances the

likelihood of finding employment and enjoying a decent purchasing power and

standard of living.

The Scholarship Programme, which in its initial

stage was affiliated with Cordiplán (Office of Coordination and Planning of the

Presidency of the Republic), became part of the "Gran Mariscal de

Ayacucho" Foundation on July 1, 1975. This change granted it greater

autonomy in decision-making and improved administrative efficiency.

The transition to a Foundation, as enabled by

Decree No. 1000 of July 1, 1975, was further complemented by Decree No. 1332 of

December 16, 1975, from the Presidency of the Republic, specifically stating

that the Foundation, as a non-profit private entity, would be administered by a

Board of Directors consisting of the Foundation's President (an appointee and

removable by the President of the Republic) and four directors representing the

Ministries of Education, Mines and Hydrocarbons, the National Council for

Scientific Research, and Cordiplán.

Venezuela is one of the few countries in the

world with significant potential for non-polluting hydroelectric energy

generation, supporting the industrial sector and job creation. This, combined

with the extraordinary potential of aluminium as an important driver for

development, considering Venezuela's vast resources of bauxite,

hydroelectricity, and natural gas, unfortunately represents a substantial

option that we haven't effectively harnessed for economic development and

diversification, as well as the generation of well-being, based on the

efficient production of this metal.

Both the projection and the behavior of the

demand for aluminium consumption, as well as global price trends, have shown

sustained growth for decades, as illustrated in the following charts and links.

Demand in the consumption of

aluminium

Aluminium prices

https://twitter.com/imeryvenalum/status/1583512018396381185

En Bahrain hicieron su Siembra Petrolera en el

Aluminio

https://twitter.com/imeryvenalum/status/1591002946971799552

OMÁN es otro de los Países Árabes que hizo su Siembra

Petrolera en la Industria del Aluminio

https://twitter.com/imeryvenalum/status/1587045829482844160

Según el Instituto Internacional del Aluminio, cada

trabajo directo de esta industria genera al menos 3,75 empleos indirectos

https://twitter.com/imeryvenalum/status/1577218679355322368

The Gulf Aluminium Industry: A legacy of 5 successful

decades, 6 aluminium smelters

In this document, we aim to illustrate the

trajectory observed by Industria Venezolana de Aluminio, C.A., CVG Venalum,

from the perspective of the training and development received by its personnel,

as well as the operational, technical, and managerial evolutionary process,

along with the results achieved over three decades (1978-2008). This journey

led CVG Venalum to the effective assimilation and mastery of acquired

technologies, as well as the development and design of proprietary technologies

that enabled the company to attain world-class efficiency and productivity

results, sustainability, and technological sovereignty.

My

Experience as a Gran Mariscal de Ayacucho Scholarship Recipient (1976–1980)

Upon completing my second year at Simón Bolívar

University in 1975, I received notification of acceptance into the Gran

Mariscal de Ayacucho Scholarship Programme to pursue undergraduate studies in

England.

In early 1976, I traveled to Manchester, where

I undertook an English language course. In September of that same year, I

commenced my studies in Metallurgy at Brunel University in London, under the

guidance of Professor Bernard Davies.

This was a "sandwich" degree programme

that extended over four years (one year longer than the traditional bachelor’s

programme). During the first three years, students spent six months at the

university, with the remaining six months dedicated to training within the

British industry.

The six months of industrial training were

carried out under contractual agreements with the companies and in compliance

with agreements established with the Workers' Union.

During that time, the Venezuelan Aluminium

Industry, CVG Venalum, was in the construction phase and would utilize the

Aluminium Reduction Technology from Reynolds Metals Company, USA.

Representatives of this company met with professors of the Metallurgy Department at Brunel University to plan the

training of Venezuelan students at the British Aluminium Company in Scotland,

where they had their Aluminium Reduction Plants.

In the first year, I had the wonderful

opportunity to engage in this training programme in Scotland. During the second

year, I undertook training within the Research and Development Department,

focusing on aluminium alloys, at the London & Scandinavian Metallurgical

Company in England. In the third year, I gained experience at the aluminium

rolling and extrusion plant, Alcan, Aluminios de Canadá, in Wales.

In the fourth and concluding year, I dedicated

my efforts to my undergraduate thesis project, which centered on the oxidation

of molten aluminium-magnesium alloys. This research was financially supported by Alcan

Laboratories in England.

Year 1977

Training conducted at the British Aluminium

Company, Kinlochleven, Scotland. Söderberg Type Reduction Cells of 40

Kiloamperes.

Video: ALUMINIUM

REDUCTION CELLS AT KINLOCHLEVEN, from minute 24:45 to minute 26:17

Power UK

Covered Aspects:

- Basic and practical fundamentals of the aluminium reduction process.

- Study and control of contamination levels produced during the reduction process.

- Measurement of the electrical resistivity of the cathodes used in electrolytic cells.

- Measurement of the anodic

profile of the cell.

Year

1978

Training

conducted at the Research and Development Department of London & Scandinavian

Metallurgical Company, Ltd, Rotherham, England.

Projects:

- Manufacturing of an exothermic compound for the repair of steel industry ladle base.

- Study of the mechanical properties of welds in some aluminium alloys.

- Effect of boron on the electrical conductivity of Al-Ti alloys.

NOTE: As an illustration, the offer received

for the second training in 1978 from the London & Scandinavian

Metallurgical Company Limited is shown, which consisted of an annual base

salary of 3060 British pounds.

Year

1979

Training

conducted at ALCAN SHEET Ltd, Rogerstone, Wales.

Covered Aspects:

- Basic and practical

fundamentals of aluminium casting, extrusion, and rolling processes.

Projects:

- Research on the formation of white spots on rolled products of certain aluminium alloys.

- Research on the tolerance limits of mechanical properties of certain aluminium alloys.

- Routine control of annealing

furnaces for aluminium alloy sheets.

Year

1980

Undergraduate Thesis: "Morphology of oxide

films formed on the surface of molten Al-Mg alloys employing techniques such as Thermogravimetry, X-ray Diffraction, Electron

Diffraction Microscopy, and Scanning Electron Microscopy with microprobe

analysis.

I presented the results of my thesis work at

ALCAN Research Laboratories in Banbury, Oxon, England. The same work was awarded the CONICIT LONDON Prize

for the best research work conducted by a Venezuelan student in the United Kingdom,

granted by the Venezuelan Embassy in London.

After completing my studies in Metallurgy at

Brunel University, I started my career as a cell line supervisor at Industria

Venezolana de Aluminio, C.A., CVG Venalum, in November 1980. I continued

to serve the company until 2011.

TRAINING AND

DEVELOPMENT PROCESS AT CVG VENALUM

This was a comprehensive process that

encompassed all areas of expertise, including technical aspects (production,

process engineering, quality control, process control, maintenance) as well as

administrative procedures, which were inherited from the technology provider,

Reynolds Metals Company.

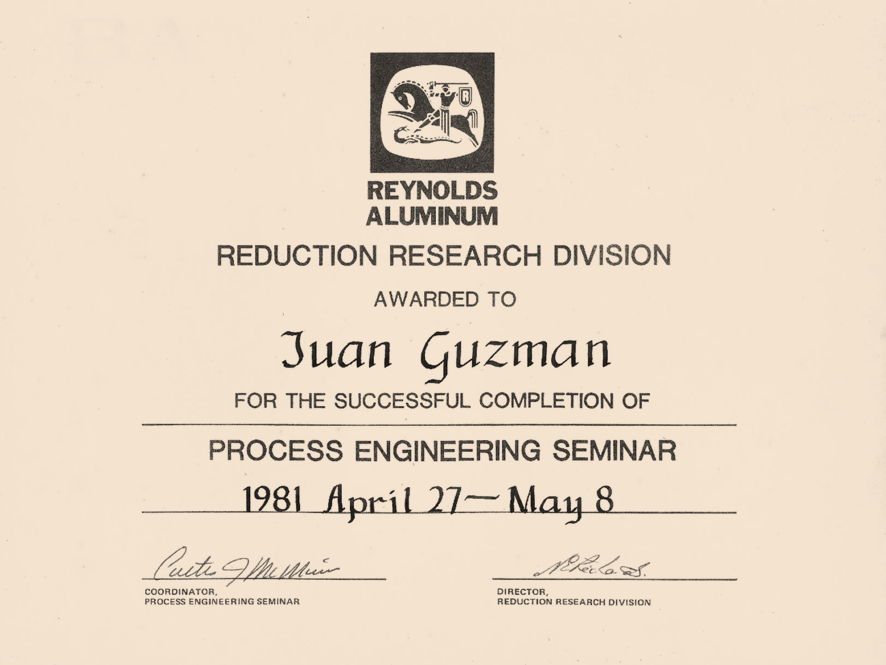

Between April 27 and May 8, 1981, a group of

engineers from the Technical Department of CVG Venalum was sent to the United

States to attend the Seminar on Process Engineering conducted by the Reduction

Research Division of Reynolds Aluminium.

Distinguished experts in the field of Aluminium

Reduction Technology, Drs. Alton Tabereaux, Curtis McMinn, and Nolan

Richards, the latter being the Research and Development Manager of Reynolds

Metals Company, were among the professors who delivered the seminar's topics.

Starting from the second semester of 1981, and

for approximately a year, the technicians in the reduction area of CVG Venalum

received on-site training on the fundamentals of aluminium reduction process, operations and engineering. The training aimed at mastering the know-how of the

specialty and was organized by the Japanese aluminium company, Showa Denko (20

percent of CVG Venalum's foreign capital is subscribed by the Japanese

consortium comprised of Showa Denko K.K., Kobe Steel Ltd., Sumitomo Chemical Company

Ltd., Mitsubishi Aluminium Company Ltd., and Marubeni Corporation). Both the

group of Japanese technicians and the training were coordinated by the aluminium

reduction technology specialist, Dr. Takahiro Suzuki.

Based on this acquired knowledge and with the

objective of creating a knowledge multiplier effect, courses were structured

and delivered to personnel in operations, maintenance, quality control, and

process engineering.

Postgraduate studies in Norway

Between 1983 and 1986, I was awarded a scholarship by Industria Venezolana de Aluminio, C.A., CVG Venalum, which allowed me to pursue doctoral studies at the University of Trondheim, Norway. During my stay, I had the honor of working under the guidance of Professor Kai Grjotheim, who specialized in Aluminium Reduction Technology, and Professor Harald Øye, specialist in Carbon Technology applied to the aluminium industry, including Anode and Cathode Technology.

KAI

GRJOTHEIM

Professor Kai Grjotheim garnered unquestionable global recognition in the realm of Aluminium Reduction Technology and played a pivotal role in co-authoring academically significant works, including:

"Aluminium Smelter Technology: A Pure and

Applied Approach," co-written with Barry Welch.

"Understanding the Hall-Héroult process

for the production of aluminium," in which he served as an editor

alongside Halvor Kvande.

"Aluminium Electrolysis: The Chemistry of

the Hall-Héroult Process," in which he was also a contributor.

HARALD

ØYE

Professor Harald Øye made a significant mark on

international aluminium industry and education. Since 1982, he spearheaded the

annual Trondheim event known as "The International Course on Process

Metallurgy of Aluminium." Moreover, much of his subsequent scientific work

is documented in the monograph titled "Cathodes in the Aluminium

Industry," co-authored with Morten Sorlie. This work has been published in

English editions in 2010, in Russian in 2013, and in Chinese in 2015.

In recognition of his outstanding work, in

1997, Professor Harald Øye received the Research Council of Norway's Researcher

of the Year award. Additionally, in 1999, he was distinguished as a Knight of

the First Class of the Royal Norwegian Order of St. Olav for Technical

Research, an honor bestowed by King Harald V of Norway.

Norwegian

University of Science and Technology, NTNU

Other Venezuelans, also graduates and

recipients of the Gran Mariscal de Ayacucho Scholarship Programme, in the United

States, England, and other locations, had a similar experience. They

subsequently received on-site training at alumina production plants in

Australia and the United States, forming the successful technical and

managerial team of Interalúmina - Bauxilum.

PLAN FOR

THE ACQUISITION AND ASSIMILATION OF TECHNOLOGIES INCORPORATED IN THE

MODERNIZATION AND V-LINE PROJECTS

As part of the plan for the acquisition and

assimilation of technologies to be incorporated in CVG Venalum's modernization

and V-Line projects, a significant number of its employees attended the annual

event "The International Course on Process Metallurgy of Aluminium"

at the University of Trondheim, Norway, in 1987. They also participated in

training programmes offered by Norsk Hydro in the fields of Aluminium Reduction

Technology and Carbon Technology for anode and cathode manufacturing, which

took place at Årdal plant facilities.

Årdal

Aluminium Reduction Plant, Norway. Photo: Hydro

The

Multiplying Effect of Acquired Knowledge

As a commitment, all the wealth of knowledge

and experiences gained, documented in various reports prepared by the training

participants, was imparted to operational, engineering, and maintenance

personnel as a multiplying effect for the training of future generations,

nurturing talent in all areas of the plant.

LEARNING THROUGH THE TECHNOLOGICAL DEVELOPMENT

PROCESS. DESIGN OF THE V-350 ALUMINIUM REDUCTION CELL

The central element of the Hall-Héroult process

for aluminium production is the electrolytic cell, with cell production being

proportional to the operating current. This relationship between production and

electricity has led to the design of cells operating at higher amperages with

the aim of increasing production and plant productivity.

Designing efficient high-amperage aluminium

cells is no easy task, and to achieve this, it requires the formation of

multidisciplinary teams capable of interacting and aligning the design

commitments of the different cell components with their individual operation

and their influence on the final performance of the cell.

Special emphasis must be placed on

electromagnetic design because, due to the large currents flowing through the

cells, the liquid aluminium tends not to be at rest, affecting the cell's

efficiency and potentially hindering its operation altogether.

The design of the cell lining is also crucial,

as it governs, among other aspects, the cell's lifespan.

Mechanical design should encompass not only the

required rigidity to withstand the stresses to which the cell's metal structure

is subjected but also the meticulous consideration of all moving parts. These

crucial components necessitate a design approach that strikes a balance between

robustness, functionality, and ease of operation and maintenance.

Up to this point, all the mentioned design

elements are managed through the creation and utilization of intricate

mathematical models, facilitating computer-aided design. This approach serves

to reduce the requirement for prototypes and industrial-scale testing.

Another significant aspect pertains to the automatic

control system. This system depends on a profound comprehension of the aluminium

reduction process and the formulation of control routines that are transformed

into computer programmes. These programmes control the mechanical components of the

cell to execute a range of tasks, such as managing alumina and additive feed,

adjusting operational variables, considering events, and more.

Finally, once the cell is designed, it must be

operated and tested, adjusting, if necessary, some of its designed components

and optimizing its operation before industrial use.

This is an important aspect to mention because

the industrial production of aluminium is carried out in units called production

lines. These lines consist of a set of more than 300 cells, as in the case of

the VI and VII Lines of CVG Venalum, electrically connected in series.

Design of the potrooms and systems related to the reduction

line

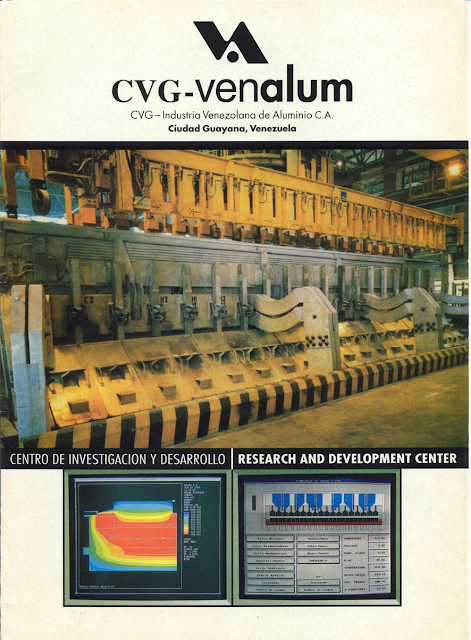

Venezuelan Aluminium Industry, C.A., CVG Venalum. In the background, the design of the capacity expansion project for lines VI and VII. Photo and Design: CINTAL

The task of designing an electrolytic cell for

aluminium production is, as demonstrated, a complex endeavor. Consequently, the

aluminium industry currently faces a shortage of technology providers in the

reduction sector.

This scarcity of providers has led to elevated

licensing costs and substantial profits for companies that specialize in this

field, rendering it a highly lucrative economic sector.

Furthermore, the CVG Venalum team, operating

independently from commercial ties to any specific firm, collaborates directly

with auxiliary equipment providers for aluminium plants. This collaboration

plays a pivotal role in cost reduction as it allows for the impartial selection

of auxiliary equipment, thereby optimizing the technical and economic aspects

of any project utilizing the V-350 Cell.

The construction of both the experimental cell

line and the facility where the Research and Development personnel would

operate took place at the end of the V-Line. This involved utilizing the

current from the V-Line (220-230 kA), which was later increased to 300-330 kA

using the booster rectifier unit. Additionally, crane services for the cells and

other auxiliary services from the V-Line were utilized in this process.

This marked the commencement of operations for

the Research and Development Centre of Industria Venezolana de Aluminio, CVG

Venalum.

The Prototype V-350 Line has been operated and

optimized since 1990 by the Research and Development Management of CVG Venalum.

Additionally, the design of the V-350 cells and their efficiency have been

audited by international experts in the aluminium industry.

TECHNICAL

AUDITS OF THE ALUMINIUM REDUCTION TECHNOLOGY DESIGN, THE V-350 CELL

The process of technical auditing signifies the

pinnacle of expertise within the Research and Development team. It involves

cutting-edge designs for aluminium reduction cells, which, for the first time

worldwide, operated at amperage levels exceeding 300 kiloamperes by 1990.

Warren E. Haupin

Warren Haupin graduated in Electrochemical

Engineering at Penn State in 1943. He was a Senior Research Engineer for

Aluminum Company of America (Alcoa), where he worked for 40 years. He published

many articles and acquired numerous patents, including one for aluminum can

manufacturing. He taught aluminum metallurgy at the University of Norway for 19

years.

Electrometallurgy of Aluminum

WARREN

E. HAUPIN and WILLIAM B. FRANK

https://link.springer.com/chapter/10.1007/978-1-4684-3785-0_5

Electrode

Reactions in Hall- Héroult Cells

https://link.springer.com/chapter/10.1007/978-94-009-3863-2_23

Haupin, W.E. and Frank, W.B., Chapter 5, Vol. 2, Comprehensive Treatise of Electrochemistry, eds. Bockris, Conway, Yeager and White; Plenum Publishing Corp., New York, N.Y.,1981, p. 308

These technical audit processes were

coordinated by Dr. Jesús Imery on behalf of the Research and Development

Centre.

Dr. Jesús Imery, upon graduating in 1986, began

working at Industria Venezolana de Aluminio, CVG Venalum, in the newly created

Research and Development unit. He initiated the Conceptual Design of the V-350

Cell and the experimental cell line. He later focused on the development of

mathematical models for calculating current distribution and electromagnetic

fields in aluminium reduction cells, which he used for the optimized design of

the busbar system. This led to the successful operation of a Hall Héroult cell

for the electrolytic production of aluminium with a current intensity exceeding

300 kA, published at the Light Metals Conference in the United States in 1989.

J.Imery. Electromagnetic optimization of the V-350 Venalum Cell. Light Metals 1989, p.p. 211-214.

This is the design that generates the patent protecting the industrial property of the V-350 cells in 1990: Electromagnetic optimization of the electrolytic cell for aluminum reduction.

Tipo: Invención

Inscripción:

No: 90-0830. Fecha: 08/06/1990

Registro:

No. 55.077

He also contributed to the design of the lining

of the V-350 cells and played a crucial role in their setup, tuning, and

characterization.

The year 1990 marked the successful start,

commissioning, and performance of the Venezuelan Aluminium Reduction Technology,

the V-350 Cell, designed by Venalum engineers. The purpose was to develop

proprietary technology for CVG Venalum, which would serve as technology for new

aluminium projects in Venezuela, both for Venalum and for privately funded

international ventures in the country. This initiative was supported by the

Minister of State and President of the Corporación Venezolana de Guayana,

Engineer Leopoldo Sucre Figarella.

In this context, when we take into account

Venezuela's abundant resources of bauxite, hydroelectric power, and natural

gas, and the potential for diversifying its economy through efficient aluminium

production, the technologies and knowledge acquired become strategically

crucial for the country's future. This is achieved through the development of CVG

Venalum's proprietary reduction technology: the V-350 Cell.

- V-350 is proprietary technology.

- It is cutting-edge technology.

- Thoroughly tested.

- Of international caliber.

- Guarantees low investment and operational costs.

- Empowers CVG Venalum (and consequently the company that uses this technology through it) to secure better pricing and financing conditions for the equipment and materials associated with a reduction line.

- Avoids high technology licensing fees, as well as those for consultations and training.

- Eliminates all expenses related to overseas travel, as well as costs for foreign personnel traveling to the country due to the use of foreign technologies.

- Prevents capital outflow.

- Possesses a high local component.

- Almost all of the metalworking and busbar construction for Cell V-350 was performed by companies in Guayana.

- It has contributed to the technological knowledge of the Venezuelan aluminium industry and has prompted the development of materials and equipment that replace those previously imported.

- It has been audited by international experts, endorsed for the construction of expansions and/or new aluminium plants.

- Its use has been requested by internationally renowned companies.

- Companies of international repute have shown interest in commercializing this technology.

- It has been selected as the subject of articles published by international magazines.

- It has been accepted at prestigious international congresses.

100% Venezuelan Reduction Technology.

The V–350 Cell

Prebake Cell Technology: A

Global Review

https://www.tms.org/pubs/journals/JOM/0002/Tabereaux-0002.html

THE V-350 ALUMINIUM REDUCTION CELL

The Design and Development of High Amperage

Cell Technology for aluminium reduction, undertaken by CVG Venalum's Research

and Development Group, represents a significant milestone in the history of

Science and Technology in Venezuela and a global breakthrough in the aluminium

reduction field. This achievement marked the world's first successful design

capable of operating at amperage levels exceeding 300 kiloamperes in 1990.

V-350 was the only high amperage cell technology operating at amperage levels exceeding 300 kiloamperes between 1990 and 2000, before any other successful technology design from any country worldwide. As reported by Dr. Alton Taberaux in the Journal of Metals, JOM, 52 (2) (2000), pages 22-28, by the year 2000, the only cells operating at the maximum amperage level of 320 kiloamperes in the aluminium industry worldwide were:

· The V-350 Cell from CVG Venalum, Puerto Ordaz, Venezuela, and

· The P-320 Cell, Pingguo, China.

"Venalum in Puerto Ordaz, Venezuela,

developed five P-point feed V-350 cells side by side, four side risers, with 36

anodes operating at 320 kA in its development line."

SPECIALIZED TECHNICAL ASSISTANCE TO CVG ALUMINIUM COMPANIES AS A BYPRODUCT OF RESEARCH AND DEVELOPMENT INITIATIVES

These initiatives of specialized technical

assistance encompassed the following key activities:

- Technical Support to the Venalum Plant: Our main focus of technical support to the CVG Venalum plant specifically extends to the reduction areas, carbon plant, casting processes, and the expansion project, lines VI and VII within CVG Venalum.

- Boosting

the Aluminium Sector: Our commitment to the aluminium sector also included

critical efforts, which comprised:

· Expansion of CVG Alcasa, Line V.

· Enhancing the production capacity of CVG Cabelum.

· Developing a territorial occupation model for bauxite-alumina operations.

· Crafting a comprehensive Aluminium Sector Strategic Plan.

These endeavors were undertaken with precision and dedication, serving as a testament to our commitment to advancing the capabilities and efficiency of CVG Aluminium Companies through our collaboration with CVG Venalum's research and development initiatives.

TECHNICAL

ASSISTANCE TO CVG VENALUM

During the privatization process of CVG's

aluminium companies, Venalum had recently been modernized with new technologies

incorporated into the construction of the V-Line.

Ten years after the unsuccessful privatization

process, the smelter continued to operate and produce at its installed capacity

of 430,000 tons per year, with world-class efficiency and productivity results

until 2008, when the power supply was suspended.

Between January 1998 and December 2008,

Venalum's sales revenue amounted to around 8 billion US dollars ($8,000 million

US).

CVG Venalum's operational conditions, as well

as its management and administration, demonstrated internationally the

magnitude of the extraordinary business that results from the integrated aluminium

industry when managed and administered with criteria of excellence.

In 2004, at the request of Marubeni

Corporation, a meeting was held between this corporation, Corporación

Venezolana de Guayana, and CVG Venalum in Puerto Ordaz to discuss with the

Japan Bank for International Cooperation (JBIC) the tentative financial proposal

offered by Marubeni Corporation for the construction of CVG Venalum's VI Line.

Japanese Banks Interested in Financing CVG Projects

Banca japonesa quiere financiar

proyectos de CVG

Venezuelan Aluminium Industry, C.A.,

CVG Venalum. In the background, the design of the capacity expansion project

for lines VI and VII. Photo and Design: CINTAL

As proven worldwide, well-managed and well-administered aluminium business never becomes an economic burden for the state.

With its revenues and savings, in the short,

medium, and long term, it ensures the coverage of all its operating,

administrative, financial costs, payment of taxes to the government, major

maintenance, and plant improvements, as well as the economic strength to

finance its expansion projects for production capacity, growth, and

diversification with its own resources.

Industria Venezolana de Aluminio, CVG Venalum, still in times of

operational, technical, and managerial excellence. Source: La Noticia, CVG Venalum,

Año 2, Nº 04, Enero-Febrero de 2003

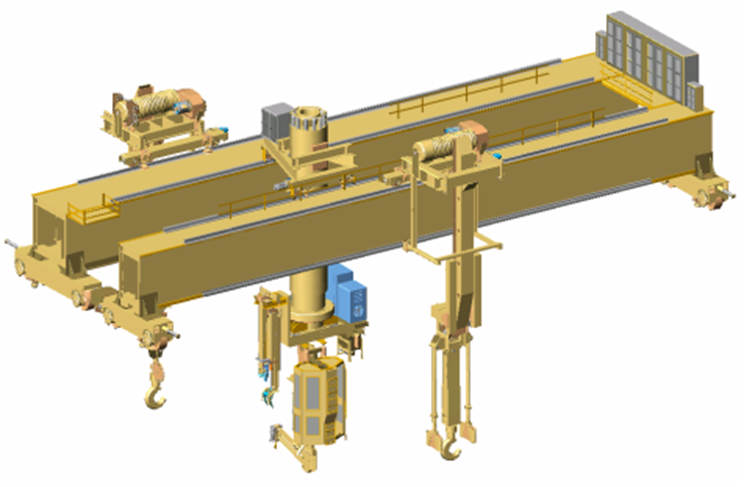

ENGINEERING AND PROJECT MANAGEMENT OF THE VI LINE

To the initial achievements in the development

of the V-350 Cell, a result of efficient project management, significant

nationally constructed engineering elements have been added. In this second

phase of the project, the Research and Development Management, supported by a

high-level multidisciplinary team with technical and managerial expertise,

carries out the engineering and project management of the VI Line Project, the

first phase of the company's expansion project.

This integrated process of technology,

engineering, and management conducted by the Research and Development

Management for the VI Line Project is beginning to yield significant results.

These include the design of a domestic proposal for specialized cranes in the

reduction area, which will enable CVG Venalum to have its own cranes for the

P-19 cells.

In a similar vein, the design of gas treatment

plants, materials handling and transportation systems, decanting and crucible

cleaning stations, hull straighteners for cells, cell control systems, tilting

furnaces in the casting area, ingot machines, and more have been initiated.

Of marked importance is the fact that many of

the developments resulting from technological innovation in the national aluminium

industry (design of key auxiliary plants and specialized equipment for a

smelter, such as materials handling, storage, gas treatment plants, specialized

cranes for the reduction process, etc.) will be compatible or can be

extrapolated to other areas of the national economy with needs in other

productive sectors.

For example, materials handling technologies can

be used in handling agricultural products such as rice, corn, beans, sugar,

etc. Gas treatment plants, once adapted, can be used in all industrial processes

that require them, and retention and melting furnaces can be used by

metallurgical companies, among others. Another area of action will be the

identification of parts and components that tend to go out of production by

their manufacturers, which can be designed and manufactured locally, thus

avoiding incurring significant replacement costs for equipment that could be

prevented.

Thus, CVG Venalum, through its Research and Development Management, has dedicated efforts to design all the auxiliary plants and equipment related to a smelter, while maintaining the strong intention of putting its technical and managerial expertise at the service of sister companies in CVG and the national industrial sector, attributes necessary to embark on the path to technological independence.

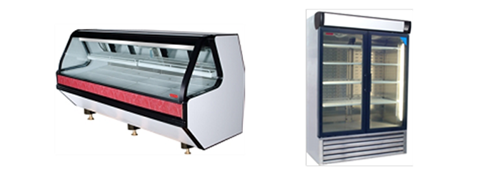

ALUMINIUM MANUFACTURING PROJECTS

These initiatives, oriented towards the design, promotion, construction,

commissioning, and technical operation consultancy of aluminium manufacturing companies, have already advanced the conceptual engineering of several projects

under the Research and Development Management. Some of these projects are

listed below.

It is important to mention that, based on the fact that various

components of the structures to be used in these projects are manufactured

using aluminium as raw material produced by the smelters in Venezuela and other

aluminium processing companies such as extrusion and rolling mills, the

construction of these plants not only helps increase the level of aluminium value addition in our country but also contributes to the

productive linkage between various national aluminium manufacturing companies,

with the evident benefits that arise from this interrelation among them.

Additionally, the design, promotion, construction, and operation of

companies related to aluminium manufacture encompass essential production

goods for society, addressing sectors such as food, healthcare, housing, etc.

The expected benefits include the following:

- Increased value added in the aluminium

production chain with significant volumes of medium and high-complexity

parts and components.

- Formation of productive linkages between

various national aluminium manufacturing companies.

- Supply of inputs to the national

manufacturing industry, especially the automotive sector, electrical

sector, and household appliances with the potential to enter any of the

production chains of the national manufacturing sector due to their

versatile applications.

- Encouragement of the national production

of fully assembled equipment since there would be manufacturing capacity

for parts and components serving as inputs for their production.

- Generation of products that, in addition

to exhibiting good profitability, have strategic significance for the

nation due to their impact on social benefits.

- Contribution to public institutional

management in support of sustained impact on promotion strategies in

response to the quality of life needs of Venezuelans, especially in

housing, food security, etc.

- Taking firm steps towards the

consolidation of Productive Sovereignty by stimulating research, design,

and development of production chains supported by the generation of

proprietary manufacturing technologies.

- Increase in non-traditional exports.

- Generation of

sustainable employment.

MANUFACTURE OF ASSISTANCE EQUIPMENT AND HOSPITAL FURNITURE

MANUFACTURE OF STORAGE REFRIGERATED ROOM

EQUIPMENT

MANUFACTURE OF ALUMINIUM ALLOY BOATS

MANUFACTURE OF PARTS AND COMPONENTS MADE OF

ALUMINIUM ALLOYS

MANUFACTURE OF ALUMINIUM KEYS

MANUFACTURE OF MODULAR ALUMINIUM HOUSING

SOLUTIONS

TECHNICAL

ASISTANCE FROM R&D TO CVG ALCASA

During 2005, Drs. Jesús Imery and Juan Guzmán

were called upon to collaborate with the management of the newly created

Ministry of Basic Industries and Mining, commencing their directorial duties as

members of the Board of Directors of CVG Alcasa, where they successfully formed

a working team that swiftly set in motion all the electrolytic cells of Line

III.

TECHNICAL ASSISTANCE FROM R&D TO CVG

BAUXILUM

In 2005 and the beginning of 2006, Dr Jesús

Imery presided over the Board of Directors at CVG Bauxilum. In addition to his

leadership, a group of engineers from the Research and Development Management,

along with other professionals from the administrative divisions of CVG

Venalum, constitute the board.

To alleviate a tense work environment, a

participatory management approach was introduced. Even a contentious document

previously introduced by the workers' union during the company's prior

administration had to be addressed.

By 2005, CVG Bauxilum had surpassed its

historical production records, substantially improved the work environment, and

reported substantial net profits. Furthermore, it is prepared to advance its

expansion project to produce over three million tons of alumina annually.

The management of CVG Bauxilum extended its

influence by advocating at the national executive level for the establishment

of a caustic soda plant, which accounts for over 70% of the company's raw

material budget.

Recognizing the imperative to enhance the

value-added to our natural resources and stimulate sustainable economic

endeavors, we actively promote the industrial utilization of granite deposits

discovered and studied in areas neighboring the bauxite mine. The Presidency of

the Republic sanctioned the necessary funds to undertake this project.

CVG Conacal collaborated closely with CVG

Bauxilum to construct a lime plant that would cater to the future requirements

of both companies, as well as the new steel company planned by the Ministry of

Basic Industries and Mining.

Furthermore, a strategic partnership with

Saint-Gobain was fostered and solidified to establish a plant in Puerto Ordaz

dedicated to the production of proppants. This crucial input is employed to

optimize gas and oil well operations and was previously entirely imported by

PDVSA.

TECHNICAL ASSISTANCE FROM R&D TO CVG

CABELUM

A segment of the Research and Development Management Centre, in collaboration with other professionals from the administrative departments of CVG Venalum, assumed key roles in the company's management. They proactively participated in various plant activities, yielding the following notable results, among others

- Halting equipment deterioration by proposing a structured and planned recovery strategy to restore reliability levels to the minimum expected standards.

- Reorganizing the Marketing Management, including relocating the office from Caracas to Ciudad Bolívar, reviewing signed contracts, and implementing a sales strategy.

- In 2005, the change in the premium for conductor sales was achieved, increasing from 430 US$/t to 950 US$/t. Additionally, the premium for wire rod sales was raised from 180 US$/t to 400 and 475 US$/t.

In October 2005, a remarkable production

milestone was reached in wire rod, with a total output of 1,643 tons. This achievement was the result of

strategic adjustments made to our processes and equipment, all carried out

using our own resources and diligent maintenance efforts. Notably, this

accomplishment marked the first time in nine years that monthly production

target was exceeded. It stands as a testament to the collective dedication

of our employees and highlights the company's potential to become a significant

player in wire rod and aluminium conductor production, all without requiring

substantial investments.

One noteworthy milestone during this period was

the reactivation of the O.T.T winder on the rolling line, which had remained

dormant for over eight years. The Maintenance Management team at CVG Venalum played a pivotal role in

this revival by constructing a new hydraulic unit and fine-tuning the winding

system. Furthermore, the automatic cutting system underwent modifications and

received valuable support from our plant personnel.

To bolster the reliability of our rolling line,

we also took the initiative to replace the outdated AC/DC converters that

powered the primary motors of the casting wheel, conveyor, and rolling mill.

The previous converters had become obsolete, with no spare parts available in

the market, resulting in frequent, unexpected breakdowns.

Throughout the years from 1998 to 2004, many

pieces of equipment received minimal maintenance attention and operated at

significantly reduced capacities.

Following a diagnosis performed by the Research

and Development Management's personnel in 2004 within the production area, a

project for technological adaptation and increased production up to 60,000

t/year of conductors was proposed, thereby enhancing the company's

profitability.

These achievements underscore our commitment to enhancing operational efficiency and optimizing our overall performance at CVG CABELUM.

CVG Cabelum had access to this funding, which was

approved as a loan by CVG in accordance with Resolution DIR 9125 dated

12/14/2005.

TRAINING

RESEARCH AND DEVELOPMENT STAFF AT THE MASTER'S AND DOCTORAL LEVELS

Starting in 1992, a segment of the

multidisciplinary team from the Research and Development Centre, through an

agreement between Industria Venezolana de Aluminio, C.A., CVG Venalum, and the

National Council for Scientific and Technological Research (CONICIT),

participated in master's and doctoral degree programmes in fields such as

Systems Engineering, Computer Science, Telematics, Instrumentation, Electronic

Engineering, Mechanical Engineering, and Materials Engineering.

These programmes took place in England, the

United States, and Spain, and it was the only agreement of its kind established

and implemented between the National Council for Scientific and Technological

Research, CONICIT, and the industry.

The agreement between the company and the

Venezuelan Council of Scientific and Technological Research, CONICIT, aimed to

create a highly academic group with prior industrial experience to complement,

increase, and consolidate its specialized technical support capacity for the

Aluminium Sector, as well as to implement policies with a multiplier effect on

this knowledge and expertise. These would be used both for training the next

generations and enhancing the technical skills of the company's staff.

Members of this high-level group have served as

professors and lecturers at universities in various fields, including

Engineering and Materials Science, Mechanical Engineering, Industrial

Automation and Process Control, Information Technologies, Industrial Process

Control and Supervision Systems, Electrical and Computer Engineering, among

others.

Additionally, among the group's academic

achievements, they have acted as academic or industrial mentors for many

students, some of whom have become highly accomplished professionals working

not only in Venezuela but also in other countries, such as the United States,

Canada, and Germany.

This multidisciplinary group of high-level

professionals graduated from nationally and internationally recognized

universities and boasts extensive experience in developing and implementing

technical and managerial solutions in the aluminium industry. They have

expertise in developing technologies for aluminium production, including parts,

components, equipment, control systems, process supervision and information,

and plants.

This high-level group has worked for over three

decades within the aluminium industry, also with a high level of success in

executive positions and as members of Boards of Directors of companies involved

in bauxite exploration, extraction, handling, and transport, alumina

production, aluminium reduction, rolling, wire drawing, and electrical conductor

manufacturing.

COMPREHENSIVE AND HARMONIOUS PLANNING FOR

SUSTAINABLE DEVELOPMENT

In addition to their academic training and

their technical and managerial experience in the aluminium industry, the

Research and Development staff at CVG Venalum have gained valuable insights

from studying in countries like England and Norway. These experiences have

allowed them to assimilate the strategies employed in these nations for

structuring government policies that have led to significant growth in the

technological and productive sectors, ultimately fostering a high standard of

living for their residents.

The reconstruction of Venezuela necessitates

not only the restoration of the existing industrial infrastructure from the

late 20th century but also the planning and execution of projects aimed at

diversification and productive growth. In these endeavors, the Aluminium

Industry stands as a crucial ally in achieving these noble objectives, much

like the countries in the Cooperation Council for the Arab States of the Gulf

view this industry as a potent tool for diversifying their economy and creating

wealth and well-being.

The impact of the aluminium sector on the UAE economy

PRACTICAL RESULTS AS PART OF THE EVOLUTIONARY

PROCESS OF THE INTEGRATED ALUMINIUM INDUSTRY

In practical results, CVG Bauxilum achieved a

historic production record in 2005, producing 1,950,000 tons of alumina that

year, demonstrating the optimal condition of the refinery systems and the technical

and managerial capacity that Bauxilum had throughout most of its history, at

least until that time.

Under the management of Engineer Noel Mariño as

the General Manager of Operations, it was possible to reach the highest level

of production in the history of Los Pijiguaos Bauxite Mine in 2006, with a

production of 5,927,839 tons in crushing and 5,764,053 tons in barge loading.

THE UNSUCCESSFUL PRIVATIZATION ATTEMPT OF CVG ALUMINIUM

COMPANIES, 1996-1998

The privatization process of

the Steel Company, SIDOR, was successful. The way in which the privatization

process is carried out in the case of the aluminium companies in the

years 1996-1998:

Senior government officials

under President Rafael Caldera's administration, tasked with overseeing the

privatization process, presented aluminium companies to potential investors as

having minimal value. They justified this by emphasizing that selling these

aluminium companies was imperative for the country due to the government's

inability to finance the substantial investments needed to modernize the

entities within the Venezuelan Aluminium Corporation, which were slated for

privatization. They also cautioned that these companies would likely cease

operations within a year due to their deteriorating condition, making them

unattractive for acquisition or donation.

VENEZUELA: El sector del aluminio no tiene quien lo

compre

VENEZUELA: Agresiva privatización acompaña plan de

ajustes

VENEZUELA: Comienza cuenta regresiva para

privatizar el aluminio

FRACASA VENTA DE EMPRESAS DE

ALUMINIO EN VENEZUELA

IMPROVEMENTS

TO THE PLANT AND THE CONSTRUCTION OF THE V-LINE AT CVG VENALUM

The construction project of the V-Line and the

installation of all HAL-230 Technology Hydro Aluminium cells was completed in

the early 1990s.

Similarly, the modernization project of cells

in Complexes I and II was carried out with the following improvements:

- Installation of the conductor bar system to compensate for the cells' magnetic field.

- Point feeding system for alumina dosing.

- Aluminium fluoride feeding system.

- Automated control system for the cells.

- Information and cell

supervision system.

Improvements

were also made to the auxiliary systems in the cell rooms:

- Cranes.

- Materials handling systems.

- Gas treatment system for

environmental improvements.

With the new cell line, the V-Line, and the

modernization of cells in the Complexes, Venalum's reduction area was brought

up to date with the state-of-the-art reduction technology. It was

then ready to reap the benefits of that investment from that decade.

This technology is efficient, productive, and above all, profitable, not far from the state of the art even today in 2023.

Additionally,

improvements were made to accompany the reduction process:

- In the carbon area to introduce improvements in anode quality.

- And

in the casting area: furnaces, casting tables, for the production of

cylinders for extrusion, among other improvements.

At the time of the privatization process, CVG

Venalum had been recently modernized with new technologies incorporated in the

construction of the V-Line.

If the government agencies responsible for the privatization process claimed that CVG Venalum was so deteriorated, why did it continue to operate at the level of its installed capacity of 430,000 tons per year and achieve world-class efficiency and productivity results. Ten years after the unsuccessful privatization process, power supply was suspended in 2008.

Between January 1998 and December 2008,

Venalum's revenue from sales amounted to approximately 8 billion dollars

($8,000 million US$).

The operational conditions, management, and

administration of CVG Venalum showcased on an international scale the immense

potential of the integrated aluminium industry when it is overseen and

administered with a commitment to excellence.

Industria Venezolana de Aluminio, CVG Venalum,

still in times of operational, technical, and managerial excellence. Source: La Noticia, CVG Venalum, Año

2, Nº 04, Enero-Febrero de 2003

EXPERIENCE IN THE DEVELOPMENT AND MANAGEMENT OF

EXPANSION PROJECTS

In 2004, at the request of Marubeni Corporation,

a meeting was held between this corporation, CVG, and CVG Venalum to discuss,

in Puerto Ordaz, the tentative financial proposal offered by Marubeni

Corporation for the construction of the VI Line of CVG Venalum with the Japan

Bank for International Cooperation (JBIC).

Japanese Bank Interested in Financing CVG

Projects

Banca

japonesa quiere financiar proyectos de CVG

Venezuelan Aluminium Industry, C.A., CVG Venalum. In the background, the

design of the capacity expansion project for lines VI and VII. Photo and

Design: CINTAL

The projects for the construction of cell

lines, namely V Alcasa Line and VI and VII Venalum Lines, were developed

following the approval of all corresponding technical and economic feasibility

studies, along with budgets sanctioned by the respective government agencies.

Extensive efforts were invested in the

conceptual and basic design phases, and important part of the detailed

engineering, of the CVG Venalum and CVG Alcasa Expansion Plans. Furthermore,

substantial efforts were dedicated to securing the necessary financial

resources for project execution, as well as ensuring a stable and sustainable

supply of electricity and alumina to support their profitable operation.

Regrettably, both plans encountered an

unexpected halt during the initial phase of land preparation, without any

official notification or explanation provided.

ALUMINIUM TECHNOLOGY INNOVATION CENTRE

CINTAL

NEW TERRITORIAL MODEL

The team at the Aluminium Technology Innovation

Centre, CINTAL, designed the Conceptual Engineering for two Aluminium Cities,

located in Caicara del Orinoco and El Palmar, promoting aluminium not only as an

economic activity but also as a driver of territorial development.

CONCLUSIONS

TRAINING PROCESS IN CVG VENALUM

YEARS 1978-1986

In 1975, the construction of Industria

Venezolana de Aluminio, C.A., known as CVG Venalum, commenced, and by 1978, it

achieved an annual production of 70,000 tons. The construction of its 4 cell

lines, developed in collaboration with Reynolds Technology, was completed in

1980, resulting in an installed production capacity of 280,000 tons per year.

The workforce that received training was

predominantly guided by personnel from Reynolds Metals Company and consisted

mainly of individuals from our educational institutions. This included

middle-level technicians, INCE technicians, Higher University Technicians

(TSU), and graduates from our universities. The training was conducted at a

high level in various specializations, encompassing both technical areas

(production, process engineering, quality control, process control,

maintenance) and administrative aspects inherited from the technology provider,

Reynolds Metals Company.

In the late 1970s and early 1980s, Venezuela

started welcoming a substantial number of university graduates from

institutions worldwide through the GRAN MARISCAL DE AYACUCHO SCHOLARSHIP

PROGRAMME. Some of these graduates joined the ranks of CVG Venalum.

Between April 27 and May 8, 1981, a group of

engineers from CVG Venalum's Technical Department traveled to the United States

to attend the Seminar on Process Engineering hosted by the Reduction Research

Division of Reynolds Aluminum. Distinguished authorities in Aluminium Reduction

Technology, including Drs. Alton Tabereaux, Curtis McMinn, and Nolan Richards

(the Research and Development Manager of Reynolds Metals Company), served as

instructors for the seminar.

Commencing in the latter half of 1981, for

approximately one year, technicians from the reduction department at CVG

Venalum received hands-on training in the fundamentals of the aluminium

reduction process, operations, and engineering to master the specialized

"know-how." This training was organized in collaboration with the

Japanese aluminium company, Showa Denko, which holds a 20 percent stake in CVG

Venalum as part of the Japanese consortium comprising Showa Denko K.K., Kobe

Steel Ltd., Sumitomo Chemical Company Ltd., Mitsubishi Aluminium Company Ltd.,

and Marubeni Corporation. The group of Japanese technicians and the training

programme were overseen by the aluminium reduction technology expert, Dr.

Takahiro Suzuki.

Building on this knowledge, and with the aim of

creating a ripple effect of knowledge, courses were designed and delivered to

personnel in operations, maintenance, quality control, and process engineering.

These courses were periodically updated to ensure continued education and

expertise development.

ORIGIN

AND EVOLUTION OF THE CVG VENALUM RESEARCH AND DEVELOPMENT MANAGEMENT CENTRE

YEARS 1986-1991

In 1986, research and development activities

began with the Conceptual Design of Cell V-350 and the experimental cell line.

In 1990, a significant milestone was achieved

with the successful launch, commissioning, and operation of the 100% Venezuelan

State-of-the-Art Aluminium Reduction Technology, known as the V-350 Cell. This

cutting-edge technology was meticulously designed by Venalum's engineers with

the objective of creating proprietary solutions for CVG Venalum. It not only

served the needs of Venalum but also paved the way for potential future

aluminium projects, including those involving international private investments

in Venezuela. This forward-thinking initiative received strong support from

Engineer Leopoldo Sucre Figarella, the Minister of State and President of the

Corporación Venezolana de Guayana.

After introducing improvements to modernize its

original cells and additionally constructing the V-Line with Hydro Aluminium

Technology, CVG Venalum reached an installed production capacity of 430,000

tons per year from the 1990s until 2008 when the electricity supply was

suspended.

YEARS

1991-2000

GLOBAL VISION OF THE ALUMINIUM SECTOR

Iniciatives led by the Research and Development Centre of CVG Venalum.

A comprehensive vision aimed at maximizing the

country's hydropower potential for the most efficient development of the entire

production chain: bauxite, alumina, aluminium, and transformation.

Interaction among companies Alcasa, Venalum,

Bauxilum, Cabelum, with the goal of improving their operations and processes

through the exchange of experiences. Especially, in the case of similar

production processes in Alcasa and Venalum.

An Information Analysis System for Cells (SAIC)

was implemented for both of these companies to monitor all cells across the 7

reduction lines (2 from CVG Alcasa and 5 from CVG Venalum). This system

encompasses not only process variables but also their interrelationships,

graphical representations, as well as consumption and cost indicators.

CONICIT – CVG VENALUM AGREEMENT

TRAINING OF CVG VENALUM'S RESEARCH AND DEVELOPMENT

PERSONNEL AT THE MASTER'S AND DOCTORAL LEVELS

Starting in 1992, part of the multidisciplinary

team from the Research and Development Management participated in programmes for

specialization at the master's and doctoral levels in areas like Systems

Engineering, Computing, Telematics, Instrumentation, Electronic Engineering,

Mechanical Engineering, and Materials Science. These programmes took place in

England, the United States, and Spain, and represented the only agreement of its

kind between the National Council for Scientific and Technological Research

(CONICIT) and the industry.

The agreement between the company and the

Venezuelan Council for Scientific and Technological Research (CONICIT) aimed to

form a high-level academic group with prior industrial experience to enhance

and consolidate their specialized technical support capacity for the Aluminium

Sector. The agreement also aimed to implement policies to have a multiplying

effect on this knowledge and expertise, which could be used not only for

training future generations but also to reinforce the technical level of the

company's personnel.

Members of this group have been lecturers and

speakers at universities in fields like Engineering and Materials Science,

Mechanical Engineering, Industrial Automation, Process Control, Information

Technologies, Industrial Process Control and Supervision, Electrical

Engineering, and Computing, among other areas.

Likewise,

among the group's academic achievements, their work as academic and/or industrial

tutors of many students stands out, some of them very prominent professionals

working not only in Venezuela, but in other latitudes: the United States,

Canada, Germany.

This multidisciplinary group of high-level

professionals graduated from nationally and internationally recognized

universities and has extensive experience in the development and implementation

of technical and managerial solutions in the aluminium industry. They have

expertise in developing technologies for aluminium production, including parts,

components, equipment, control systems, supervision, and information systems,

as well as plants.

This high-level group has worked in the aluminium

industry for over three decades, holding managerial positions and serving as

members of boards of directors in companies involved in bauxite exploration,

extraction, handling, and transport, alumina production, aluminium reduction,

rolling, wire drawing, and electric conductor manufacturing.

YEARS

2001-2030

CVG VENALUM

Undoubtedly, the formation of integrated work

teams focused on TECHNOLOGY DEVELOPMENT, ENGINEERING, and PROJECT MANAGEMENT is

the key to consolidating PRODUCTIVE SOVEREIGNTY based on TECHNOLOGICAL

SOVEREIGNTY. At CVG Venalum, we are taking a significant step towards the

Technological Independence that Venezuela needs to progress towards the levels

of well-being our society requires, demands, and deserves on its path to the

global leadership position our country is destined for in this century.

During this stage of work at CVG Venalum, the

activities of technical assistance continue, but now there is a focus on

collaborating in the structuring of a National Aluminium Plan, promoting the

aluminium industry, and expanding the installed capacity. This work made significant

progress in the year 2000 when the R&D Centre coordinated the representation of the

Venezuelan Aluminium Sector at our National Pavilion at EXPO 2000 in Hannover,

Germany, and at the Aluminio 2000 Symposium in Puerto Ordaz.

In both events, the promotion of the country's

potential for efficient aluminium production was formally relaunched, reversing

the negative campaign that had been held against this vital part of the

national economy. Additionally, the new Project of the V Line of CVG Alcasa,

based on National Technology, the V-350 Cell, was presented for the first time,

along with important aspects related to the recovery of CVG Alcasa.

These early achievements

in the tireless work of rescuing and promoting the image of the Venezuelan

Aluminium Sector internationally were further enhanced in 2003 through

participations organized by the Research and Development Centre of CVG

Venalum at the Aluminium and Energy Congress in South Africa and the Commodities

Research Unit (CRU) Congress in the United States. In these forums, the new

focus for the sector was formally presented to the international aluminium business

community. In 2004, there was also participation in the TMS 2004 Congress in

the United States, where the Expansion Plan of CVG Venalum, including the Sixth

and Seventh Lines, was shared with the international community.

In line with these

activities, work was done on the conceptual and basic design of the CVG Venalum

Expansion Plan, as well as in securing the financial resources for its

execution. Likewise, in defining the guarantee of electricity and alumina

supply for the stable, profitable, and sustainable operation of these projects.

The expansion project

that had been approved and initiated at Industria Venezolana de Aluminio, CVG

Venalum, was halted without official notification in 2006.

CVG ALCASA

In 2005, the newly

created Ministry of Basic Industries and Mining called on Drs. Jesús Imery and Juan Guzmán to collaborate with its management, commencing their

directorial duties as members of the Board of Directors of CVG Alcasa. They

managed to assemble a working team that brought all the electrolytic cells of

Line III into operation in record time.

Starting in April of the

same year, both professionals were appointed as Presidents of CVG Bauxilum (Dr.

Jesús Imery) and CVG Cabelum (Dr. Juan Guzmán), respectively. The Boards of

Directors of both companies were composed of professionals from both the

Research and Development Centre and the administrative areas of CVG

Venalum.

CVG BAUXILUM

CVG Bauxilum presented a different situation.

In 2005, the company surpassed its historical production, significantly

improved the work environment, reported net profits, and was prepared to launch

its expansion project to produce over three million tons of alumina annually.

In addition, the management of CVG Bauxilum extended beyond its borders. The construction of a caustic soda plant was promoted at the national executive level, an input that represents over 70% of the raw material budget for the company.

Recognizing the need to

increase the value-added to our natural resources and generate new sustainable

economic activities, industrial use was promoted for granite deposits

discovered and studied in areas near the bauxite mine. Approval from the Office

of the President was obtained to allocate the necessary funds for this project.

Collaboration with CVG Conacal was established

for the construction of a lime plant to meet future needs for both CVG Bauxilum

and the new steel company to be built by the Ministry of Basic Industries and

Mining.

A strategic alliance with

Saint-Gobain was also promoted and consolidated for the construction of a

proppants production plant in Puerto Ordaz, a critical input used to optimize

gas and oil wells. PDVSA imported the entirety of this product. This has been

the only international private capital project consolidated in the Guayana

region.

CVG CABELUM

At CVG Cabelum, among

other things, the following results were achieved:

Preventing equipment

deterioration by proposing a structured and planned recovery plan to restore reliability

to expected levels.

Reorganizing the

Marketing Management, including relocating the office from Caracas to Ciudad

Bolívar, reviewing signed contracts, and sales schemes.

In 2005, changes were

achieved in conductor premiums, increasing from 430 US$/t to 950 US$/t, and

wire rod premiums from 180 US$/t to 400 and 475 US$/t.

October 2005 saw a record

production of wire rod, reaching 1,643 tons, exceeding the monthly production

level not achieved for nine (9) years.

The O.T.T winder in the

rolling line, which had been out of service for over eight years, was put into

operation.

From 1998 to 2004, most

of the equipment received minimal maintenance, with many of them operating at

levels as low as 30% of their installed capacity, such as the drawing machines.

A project was presented

for technological adaptation and production increase up to 60,000 tons/year of

conductors, resulting in increased profitability for the company. This project

was approved in a memorandum presented to the President of the Corporación

Venezolana de Guayana, and funding was approved as a loan by CVG, according to

Resolution DIR 9125 dated 12/14/2005.

CINTAL,

ALUMINIUM TECHNOLOGY INNOVATION CENTRE

As the President of CINTAL, Dr. Jesús Imery collaborated closely with leading researchers from CVG Venalum's Research and Development Management to establish this centre.

During

its inception, the primary focus was on consolidating expansion and economic

recovery projects for national aluminium sector companies, as well as the

development, promotion, funding acquisition, and execution of value-added

projects for primary aluminium.

CINTAL not only promoted

aluminium as an economic activity but also as a catalyst for regional

development. It designed the Conceptual Engineering for two Aluminium Cities,

situated in Caicara del Orinoco and El Palmar, respectively.

Given Venezuela's vast

potential for efficient and sustainable aluminium exploitation and the urgent

need to create jobs, improve living standards, and rectify the flawed

territorial development model that has plagued our country for decades, it is

imperative to harness the nation's full potential to achieve these vital goals.

In this context, it is

inexcusable to miss the latent opportunities that have arisen due to

Venezuela's numerous advantages for the growth of its aluminium industry, which

has consigned thousands of Venezuelans to a life of poverty.

The country is on the

brink of a transformative process, representing the last beacon of hope.

No comments:

Post a Comment