THE UNSUCCESSFUL PRIVATIZATION ATTEMPT OF CVG ALUMINIUM COMPANIES, 1996-1998

The

privatization process of the Steel Company, SIDOR, was successful. The way in

which the privatization process is carried out in the case of the aluminium

companies in the years 1996-1998:

Senior government officials under President

Rafael Caldera's administration, tasked with overseeing the privatization

process, presented aluminium companies to potential investors as having minimal

value. They justified this by emphasizing that selling these aluminium

companies was imperative for the country due to the government's inability to

finance the substantial investments needed to modernize the entities within the

Venezuelan Aluminium Corporation, which were slated for privatization. They

also cautioned that these companies would likely cease operations within a year

due to their deteriorating condition, making them unattractive for acquisition

or donation.

VENEZUELA:

El sector del aluminio no tiene quien lo compre

VENEZUELA:

Agresiva privatización acompaña plan de ajustes

Ejecutivo

ratificó privatización de las empresas del aluminio para I trimestre de 1998

VENEZUELA:

Comienza cuenta regresiva para privatizar el aluminio

FRACASA VENTA DE EMPRESAS DE ALUMINIO EN

VENEZUELA

PLANT IMPROVEMENTS AND CONSTRUCTION OF THE V-LINE IN VENALUM

The V-Line construction project and

installation of all HAL-230 Hydro Technology cells were completed in early

1990s.

In the same way, the modernization project of complexes I and II was carried out with the following

improvements:

- installation of busbar system for magnetic compensation of the cells

- alumina point feeding system

- aluminium fluoride system

- automated cell control system

- cell information and supervision system

- improvements were also made to

the auxiliary systems of the cell rooms: cranes, material handling

systems, gas treatment system for environmental protection

With the new line of cells, the V-Line, and

with the modernization of cells in the Complexes, the Venalum reduction area

was updated to the state of the art in reduction technology. Venalum was then

preparing to reap the fruits of that investment since that decade. This

technology, today, in 2023, is efficient, productive and above all profitable,

not being far from the state of the art.

Additionally, improvements were made that

should accompany the reduction process: in the carbon plant to introduce

improvements in the anode quality, and in the casting room: furnaces, casting

tables for the manufacture of cylinders for extrusion, among other

improvements.

The year 1990 also served for the successful

start-up, commissioning and performance of the Venezuelan Aluminium Reduction

Technology, The V-350 Cell, designed by Venalum engineers, and whose purpose

was the design of a CVG Venalum proprietary technology that serve as technology

for new aluminium projects, both, for Venalum and for projects with

international private investment in Venezuela, an initiative that was supported

by the Minister of State and President of the Venezuelan Corporation of

Guayana, Engineer Leopoldo Sucre Figarella.

Plaque of recognition of the Minister of State

President of the Venezuelan Corporation of Guayana, Engineer Leopoldo Sucre

Figarella on the startup of The V-350 Cell on June 9, 1990. Photo: CINTAL

Bauxilum is the company resulting from the

merger in March 1994 of the Bauxite Mine, Bauxiven (created in 1979) and the

Alumina Plant, Interalumina (created in 1977).

Subsequently, Venalum, Alcasa, Bauxilum and Carbonorca

were integrated into the Aluminium Corporation of Venezuela, CAVSA, holder of

shares for the sale process of the companies.

In practical results, for the year 2005 CVG Bauxilum closes with a historical production record by producing 1,950,000 tons of alumina that year. Additionally, Los Pijiguaos bauxite mine reached a production figure of 5,927 millions tons or 98.8% of its installed capacity in 2006 (historical production record), demonstrating the optimal conditions of the refiner’s systems, as well as the technical and managerial capacity that Bauxilum had in almost all its history. At least, until that time.

As previously mentioned, CVG Venalum had

undergone recent modernization at that time, incorporating new technologies in

the construction of the V Line.

If it is argued that Venalum was in such a

state of disrepair, why did the plant continue to operate at its full installed

capacity of 430,000 tons per year a decade after the failed privatization

process? Furthermore, it consistently achieved world-class levels of efficiency

and productivity until 2008 when the power supply was suspended.

Between January 1998 and December 2008, Venalum

generated sales revenues totaling approximately $8 billion USD ($8,000 million

USD).

The operational circumstances of CVG Venalum,

along with its management and administration, exemplified the substantial

potential of the integrated aluminium industry when it is overseen and

administered with a commitment to excellence.

In 1994, CVG Venalum’s Research and

Development Team, simultaneously with its activities, dedicated itself to

promoting the aluminium sector as one of the most important options to

accompany oil in supporting the national economy, with the organization

of the 1st. National Seminar of the Aluminium Sector,

Sensa 94.

Publication

Edited by CVG Bauxilum for workers in the Aluminium Sector

During the time of the privatization process, 1996-1998,

CVG Venalum Research and Development Team focused on structuring a National

Aluminium Plan, as well as on promoting the aluminium industry and the

expansion of installed capacity. This work shows an important advance

during 1999, and in the year 2000 the Research and Development Centre of

CVG Venalum coordinates the representation of the Venezuelan Aluminium Sector

in our National Pavilion at EXPO 2000 Hannover in Germany, and

in the Aluminium Symposium 2000 in Puerto Ordaz.

In both events, the promotion of the country’s

potential for the efficient production of aluminium is formally relaunched,

thus reversing the smear campaign that had been maintained on this important

link in the national economy. Likewise, the new Project of the V Line

of CVG Alcasa, based on the use of National Technology, The V-350 Cell, is

presented for the first time, also considering important aspects for the

recovery of CVG Alcasa.

The image of the Venezuelan Aluminium Sector

was again strengthened in 2003 through participations

organized by the Research and Development Centre of CVG Venalum in the Aluminium

and Energy Congress in South Africa, and the Congress of the Commodities

Research Unit (CRU) in the United States, where the international

community of the aluminium business was formally shown the new approach that

Venezuela would be giving to the sector. In 2004, Venalum also

participated in the TMS 2004 Congress (United States) where

the CVG Venalum Expansion Plan, which includes the Sixth and Seventh

Lines, is shared with the international community.

In 2004, at the request of Marubeni

Corporation, a meeting was held between this corporation, CVG and CVG Venalum

to discuss in Puerto Ordaz with the Japan Bank for International Cooperation

(JBIC) about the financial proposal tentatively offered by Marubeni Corporation

for the construction of the VI Line of CVG Venalum.

Banca japonesa quiere

financiar proyectos de CVG

https://www.voltairenet.org/article122748.html

Venezuelan Aluminium Industry, C.A., CVG

Venalum. In the background, the design of the capacity expansion project for

lines VI and VII. Photo and Design: CINTAL

As demonstrated globally, a well-managed

aluminium business never imposes an economic burden on the state. Through its

revenue and savings, both in the short and long term, it ensures the coverage

of all operational, administrative, and financial expenses, tax payments to the

government, significant plant maintenance and enhancements, and possesses the

financial strength to independently fund projects aimed at expanding production

capacity, fostering growth, and diversification.

Industria

Venezolana de Aluminio, CVG Venalum, still in times of operational, technical,

and managerial excellence. Source: La Noticia, CVG Venalum, Año 2, Nº 04,

Enero-Febrero de 2003

CONCLUSIONS

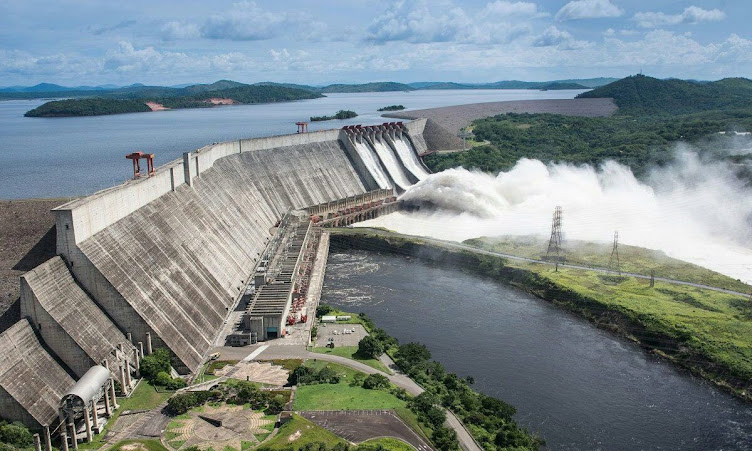

The Guayana Development Programme stands as

compelling evidence of an exceptional development planning initiative closely

tied to the advantages presented by the hydroelectric potential of the Caroní

River. This methodological framework should be applied across all productive

and service sectors, encompassing areas such as food production, agriculture,

livestock, fisheries, iron and steel, forestry, mining, high technology, and

more.

Given our current circumstances, it is

imperative that we seek the guidance and leadership of Dr Miguel Rodríguez in

structuring the Economic Recovery and Transition Plan. Dr Miguel Rodríguez's

economic adjustment program, proposed and implemented in 1989, aimed to refinance

external debt and prevent Venezuela from facing bankruptcy. This initiative

achieved remarkable success, resulting in a substantial reduction in inflation

and fostering an impressive 9% year-on-year GDP growth within just three years.

This achievement stands as a unique and unparalleled success story in the

history of the Venezuelan economy.

The vision of economist Dr Miguel Rodríguez,

which envisions Venezuela as a major exporter of products from various

productive and service sectors, should serve as our guiding light in the

process of planning for sustainable development. This vision necessitates the

implementation of policies that drive essential structural changes within the

oil sector, as well as other sectors of the economy with the potential to

become prominent export sectors.

Significant efforts have been made in Guayana

to instigate substantial structural changes that could potentially transform

Venezuela into a high-growth economy, leveraging its available resources to

emulate the successes achieved by Japan, South Korea, and China.

Thanks to Dr Miguel Rodríguez's adept

management, the Lower Caroní Development Programme saw significant acceleration.

All available resources were directed towards the completion of Macagua II. Dr Miguel Rodríguez masterminded the comprehensive investment plan for the

Caruachi Hydroelectric Power Plant. With the Tocoma Hydroelectric Plant in

operation, we would have had a minimum of two reduction plants, each capable of

producing over half a million tons of aluminium annually, complementing the full

production capacity of Venalum and Alcasa, as well as the entire aluminium

supply chain established in Venezuela.

This presented a remarkable opportunity to

fortify Venezuela's Sustainable Development for good. These two remarkable and

iconic figures, Dr Miguel Rodríguez and Eng Leopoldo Sucre Figarella, formed

a formidable team, reaffirming and ensuring the continued validity of the

Guayana Development Programme. This programme bestowed upon the country immense

strength as it approached the 21st century.

No comments:

Post a Comment