ALUMINIUM IS AN IMPORTANT DRIVER OF DEVELOPMENT

AND ONE OF THE MOST SIGNIFICANT OPTIONS TO ACCOMPANY OIL IN THE RECOVERY OF THE

VENEZUELAN ECONOMY, AS WELL AS IN THE GENERATION OF WEALTH AND WELL-BEING.

BRIEF HISTORY OF DR JESUS IMERY

Dr Jesús Imery was Research and Development Manager of the Venezuelan Aluminium Industry, CVG Venalum, President of Bauxilum, a Bauxite and Alumina producing company, and President of the Aluminium Technological Innovation Centre, CINTAL. Together with an important group of specialists from Venalum R&D Centre and CINTAL, he has worked tirelessly for more than 30 years in defense of the potential of aluminium as one of the most important options to accompany oil in the support of the Venezuelan economy, and the generation of wealth and well-being.

Additionally, Dr Jesús Imery, as a Specialist and Advisor to the aluminium industry internationally, advances in very important initiatives for the recovery, growth, and diversification of the Aluminium Sector in Venezuela, as well as in plans for countries in the region, which, having hydroelectric energy available, they advance projects for the construction of aluminium reduction plants.

Aluminium, a DRIVING FORCE OF THE VENEZUELAN ECONOMY, is one of the most important options to accompany oil in the recovery of the Venezuelan economy, and the generation of wealth and well-being, and at the same time, the area of greatest specialty and expertise of the group that worked for more than 30 years in the Research and Development Management of Venezuelan Aluminium Industry, CVG Venalum.

Venezuela stands out as one of the rare nations

globally that possesses all the prerequisites for comprehensive and lucrative

aluminium production. This unique positioning grants the country significant advantages,

positioning it as a frontrunner in this global economic sector.

Furthermore, it plays a pivotal role in

fostering growth and development while also facilitating economic

diversification, offering a non-oil alternative that contributes to foreign

exchange generation. This, in turn, directly impacts the nation's prosperity

and well-being across the short, medium, and long-term horizons.

Venezuela's potential for aluminium production and its capacity to bolster the economy should have been leveraged when CINTAL, the Aluminium Technological Innovation Centre, developed and presented plans for expanding the aluminium industry to the National Executive.

The expansion projects at Industria Venezolana de Aluminio, CVG Venalum, and Aluminio del Caroní, CVG Alcasa, which had been approved and initiated, were abruptly halted in 2006 without any official notification.

The National Aluminium Plan 2003 – 2018, consisted of reaching the production of three million tons of aluminium per year in a period of 15 years, which would generate annual income from aluminium sales in the order of six billion dollars (US$ 6,000 million). Additionally, twenty-five billion dollars (US$ 25,000 million) in accumulated investments for the sector: bauxite, alumina, aluminium.

Both, the projection and the behaviour of demand in aluminium consumption, as well as that of world prices, have been maintained as estimates since 2000, as shown in the graphs.

Demand in the consumption of aluminium

Aluminium prices

THE NATIONAL ALUMINIUM PLAN

The execution of the National Aluminium Plan leads to growth in the following sectors: energy, mining, construction and installation of alumina and aluminium production plants, creation of service companies, development of railways and highways, in addition to everything related to improvements in the community’s standard of living through the generation of 170,000 permanent jobs and 190,000 temporary jobs, with the construction of houses and their access to basic services, education, health.

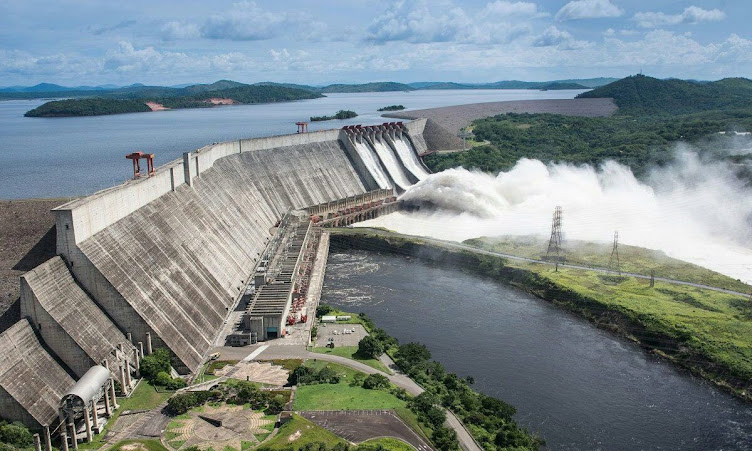

Since aluminium is added value of energy, the development of the industry implies the efficient use of the country’s energy resources, on the understanding that, in the case of the electricity sector, Venezuela is one of the few countries in the world that has a large potential for the generation of hydroelectric energy, non-polluting, to support the industrial sector and the generation of jobs and well-being.

State strategies similar to those reflected in the National Aluminium Plan have been implemented and are currently being implemented in countries such as: Canada, Norway, Australia, United Arab Emirates, Russia, China, South Africa, Mozambique, among others, receiving their communities the benefits of implementing these strategies.

This is how countries with very high standards of living, such as Norway, Australia, Canada, and Iceland, among others, have a flourishing aluminium industry, and in some cases, such as Australia, enjoy all the elements of the productive chain for the production of aluminium.

Arab countries, members of OPEC such as Venezuela, have also used the advantages associated with having electricity at a very low cost, to break into the aluminium business very aggressively. Among them we can mention Bahrain, Dubai and Saudi Arabia.

THE GULF ALUMINIUM INDUSTRY: A LEGACY OF 5 SUCCESSFUL DECADES, 6 ALUMINIUM SMELTERS

Still, countries with political situations of very high risk, as is the case of Mozambique, have undertaken installation and expansion plans for aluminium industries, and in less than 10 years of operations they almost exceed the installed production capacity of Venezuela.

HOW IS ALUMINIUM OBTAINED?

The following are the processes that lead to obtaining aluminium:

- Mining, with the extraction of bauxite

- Refining, which consists of obtaining alumina or aluminium oxide from bauxite, separating it from other oxides such as iron oxide, silicon oxide and others in very small proportions, through the Bayer Process

- Obtaining aluminium from alumina through the Hall-Héroult reduction process in electrolytic cells, where oxygen is separated from aluminium

Aluminium Productive Chain

The country has several bauxite deposits, and

studies conducted to quantify them indicate inferred amounts on the order of

over 2,500 million metric tons.

The information also indicates volumes on the

order of 1,780 million metric tons in Cedeño Municipality and 475 million

metric tons in Padre Chien Municipality, both located in the Bolívar State

(Guayana Region), where Venezuelan industries of bauxite, alumina, and aluminum

are currently in operation.

All of these reserves are greater than what is

currently being exploited in Los Pijiguaos mine, ensuring a long life for

the integrated aluminium industry in Venezuela. This also enables the creation

of new population centres with sustainable economies based on the aluminium

industry.

The average sale price of bauxite is approximately 25 dollars per ton and receives a significant added value of 330% when it is transformed into alumina. The LME price (marker of the supply and demand of the sector) for the negotiation of the national alumina is around 13% of the value of the price of one ton of aluminium, therefore, if we consider a reference price of 2,000 dollars per ton of aluminium, then the selling price per ton of alumina is $260, resulting in a 300% alumina-to-aluminium added value.

The added value chain must be considered in its entirety, that is, we must calculate the added value from bauxite to aluminium, which leads to an added value of the order of 1,690%, a fairly high value and highly competitive when compared to any productive sector.

ADDING VALUE FROM BAUXITE TO ALUMINIUM

Electric energy to obtain aluminium exceeds 20% of production costs, clearly an important added value for our energy thanks to its incorporation in the aluminium production process.

Now, since Venezuela has its own bauxite, gas, electricity and other conditions for a flourishing integrated aluminium industry, there is no doubt about its high potential to accompany the oil industry in supporting the national economy.

To this added value of the transformation of bauxite into alumina, we must mention that significant amounts of caustic soda and lime are used in the refining of bauxite, inputs that can be produced nationally, generating additional jobs. Likewise, significant amounts of natural gas and electricity are consumed in the process. Again, to this added value, we must add that, in the process of transforming alumina into aluminium, large amounts of coke and petroleum pitch are used, which can be manufactured by our national oil industry.

Aluminium can not only help the economic growth of the country, but also contribute to better land use, and a better distribution of the population, since this activity has the potential to create new centres of population concentration similar to the cases of Australia and Canada.

EXAMPLES OF THE IMPORTANCE GIVEN BY OTHER COUNTRIES TO THE ALUMINIUM INDUSTRY TO SUPPORT THEIR ECONOMIES

Leading countries in aluminium production worldwide

NORWAY

Norsk Hydro ASA, a Global and Integrated Energy and Aluminium Company with 36,000 employees in 40 countries, is the world’s fourth largest company in the integrated aluminium sector. The Norwegian government owns 43.8 percent of the company.

Norsk Hydro is a major producer of hydroelectric power. Norway is the largest producer of hydroelectric power in Europe and the sixth largest in the world. Hydraulic production can vary 60 TWh between years, depending on the amount of precipitation, and the undeveloped hydroelectric potential is approximately 34 TWh.

PLANT IMPROVEMENTS AND CONSTRUCTION OF THE V-LINE AT CVG VENALUM

The V-Line construction project and installation of all HAL-230 Hydro Technology cells were completed in early 1990s.

In the same way, Hydro Aluminium carried out the project to modernize the cells of complexes I and II with the following improvements:

- installation of the busbar system for magnetic compensation of the cells

- alumina point feeding system

- aluminium fluoride feeding system

- automated cell control system

- cell information and supervision system

- improvements were also made to the auxiliary systems: cranes, material handling systems, gas treatment system for environmental protection

Starting from an annual production capacity of 280,000 tons, original P-19 Reynolds Technology Cells, with the improvements in the complexes, and the start-up of the V-Line, CVG Venalum reaches a production of 430,000 tons/year.

With the new line of cells, the V-Line, and with the cell’s modernization in the Complexes, the reduction area of CVG Venalum was updated to the level of the state of the art in reduction technology worldwide. The company was then prepared to reap the fruits of that investment since that decade. This technology, today, in the year 2022, is efficient, productive and above all profitable, not being far from the state of the art.

Additionally, improvements were made that should accompany the reduction process: in the carbon plant to introduce improvements in the quality of the anode, and in the cast house: furnaces, casting tables for the manufacture of cylinders for extrusion, among other improvements.

Norway has the Norwegian University of Science and Technology, NTNU, in Trondheim, for education, training, specialization, and the technological support it provides to all productive and service sectors. Especially, for the areas: oil, gas, clean energies; hydroelectric, wind, solar. In the same way, for the support of the aluminium industry with the Specialization in Aluminium Reduction Technology and Carbon Technology for the manufacture of Anodes and Cathodes.

Professor Harald Øye, has had a major educational impact on the international aluminium industry by establishing Trondheim’s annual event «The International Course on Process Metallurgy of Aluminium» since 1982.

Much of his later scientific work is contained in the monograph «Cathodes in the Aluminium Industry» together with Morten Sorlie, 2010 English edition, 2013 Russian edition, and 2015 Chinese edition.

In 1997 he received this year’s Outstanding Research Award from the Norwegian Research Council. Professor Harald Øye was made a Knight First Class of the Royal Norwegian Order of Saint Olav for Technical Research conferred by King Harald V of Norway in 1999.

As a Plan for training and assimilating the technologies to be incorporated in CVG Venalum’s modernization and V-Line projects, a significant number of workers attended both, the annual event «The International Course on Process Metallurgy of Aluminium» at the University of Trondheim, as well as the training programs given by Hydro in the areas of Aluminium Reduction Technology, and Carbon Technology for the manufacture of anodes and cathodes that took place at Årdal plant facilities.

Årdal Aluminium Reduction Plant, Norway. Photo: Hydro

AUSTRALIA

Australia produces massive amounts of alumina, of which it exports a high percentage, understanding in this way that it is important to make the most of the potential that possesses, while simultaneously developing higher levels of transformation, but without condemning thousands of citizens to temporary misery, who in Australia currently enjoy a high standard of living, thanks to the notable exports of alumina.

From the analysis of the Australian case and when compared to the Venezuelan, there is no doubt that Australian society makes the most of its potential to produce aluminium to generate significant benefits for its society, a situation that to date has not been harnessed by our country.

But the difference in benefits that Australia obtains for having developed its aluminium industry more seriously than Venezuela is not only economic, since Australians have installed alumina refineries and aluminium reduction plants in different regions of their country. Thus, aluminium in Australia has helped to make better use of the territory, a condition that must soon be addressed by Venezuela through the development of the proposed projects.

CANADA

Although Canada does not have bauxite reserves, and must import both, bauxite and alumina, its aluminium production has been greater than ours with the benefits associated with that difference.

From the analysis of the Canadian case, and when compared with the Venezuelan, the first thing that stands out is that Canada, although it does not have all the comparative advantages to produce aluminium that Venezuela has, it is indisputable that Canadian society makes the most of its potential to produce aluminium. Thus, it adds important income, jobs and well-being to its community, which helps it to be one of the most stable and rich economies on the planet, while enjoying a notable distribution of social benefits when compared to the large economic powers of the western world.

Analogous to the Australian case, Canada has put forward important expansion plans for its aluminium sector, which of course, and as has been discussed, does not mean under any circumstances that no processing industries are established, but quite rightly, take advantage of the maximum any possible opportunity to generate well-being for their communities, without considering some nodes of the aluminium production network as unprofitable, or not worth exploiting.

This strategy, as in the Australian case, quickly allows the creation of important jobs in the upstream chain of the aluminium sector, while guaranteeing the metal at very enviable and attractive conditions, an excellent condition and incentive for the progressive establishment of a greater transformation park.

Of course, all growth predictions worldwide are often subject to the opportunities taken or left by the different actors, in this sense, Venezuela has lost valuable time that has been taken by its competitors.

Quality of life in Canada

BAHRAIN

This is an oil-producing country that has wisely used that potential to diversify its economy by incorporating a very important aluminium industry. For this purpose, they use gas for the production of energy, which is used for the electrolysis of aluminium.

It is important to note that Bahrain does not have bauxite reserves, a disadvantage when compared to countries like ours for the competitive production of aluminium, however, its production reaches 1,500,000 tons of aluminium per year.

UNITED ARAB EMIRATES

Perhaps the best example of an oil-producing country that has known how to sow its oil is the United Arab Emirates, a reality that is reflected in values such as a very low unemployment rate of 2.4%, and a GDP per capita that is the fourth best in the world.

Sowing the oil in aluminium

The most remarkable is that they, like us in Venezuela, have developed their own aluminium reduction technology, since they understood the enormous potential that aluminium offers to diversify their economy and benefit their inhabitants.

Furthermore, they have proudly built several production lines using their own technology, and this traditionally oil-producing country advanced a National Plan that raised aluminium production to 2,600,000 tons per year.

This line of proceeding in the United Arab Emirates has been supported by its government, who join efforts with their technicians to turn aluminium into a world-class company in the United Arab Emirates, for which they support the development of their own technologies and their massive scale, which they understand as the only way to Productive Sovereignty. Plans similar to those iniciated in Venezuela from the 1990s to 2005.

THE IMPACT OF THE ALUMINIUM SECTOR ON THE UAE ECONOMY

CONCLUSIONS REGARDING THE PLANNING OF THE ALUMINIUM SECTOR IN VENEZUELA

From all what has been mentioned about the aluminium sector in Venezuela, it can be concluded that:

- Venezuela is one of the few countries worldwide that meets all the conditions for the integral and profitable production of aluminum.

- Taking as calculation basis a price per ton of aluminium of $2,000/t, the process of transforming bauxite into aluminium leads to a value addition of around 1,690%, a high and competitive value when compared to any productive sector.

In the following graph, a trend in the international price of aluminium that exceeds $3,000/t during the current year 2022 can be observed.

International price of aluminium, Year 2022

- A production of three million tons of aluminium per year to be achieved in a period of 15 years would generate annual sales revenues in the order of six billion dollars (US $ 6,000 million). Additionally, twenty-five billion (US $ 25,000 million) in accumulated investments for the sector: bauxite, alumina, aluminium.

- The National Aluminium Plan leads to a generation of 170,000 permanent jobs and 190,000 temporary jobs.

- State strategies similar to those reflected in the National Aluminium Plan have been implemented and are currently being implemented in countries such as: Canada, Norway, Australia, United Arab Emirates, Russia, China, South Africa, Mozambique, with their communities receiving the benefits of the implementation of these strategies.

- Given that Venezuela, being one of the few countries that, having all the resources available to develop a world-leading industry, does not take advantage of these benefits, and that currently maintains very low levels of its installed capacity in operation, Colombia prepares its corresponding plans for the development of the aluminium industry aimed at meeting regional demand.

- Aluminium can not only help economic growth but also better land use, since this activity has the potential to create new centres of population concentration, as in the cases of Australia and Canada.

- The United Arab Emirates have known how to sow their oil, developing not only their capacity to produce aluminium using their energy resources, but also through an aggressive plan for technological independence, which has led them to be a designer country of their own reduction technology, with which they undertake their expansion plans, taking the destiny of their country in their hands.

- In the eighties, the President of the Venezuelan Corporation of Guayana, Engineer Leopoldo Sucre Figarella, announced a plan to increase the production of the aluminium sector to 2 million tons per year with the participation of international private investment.

- If our aluminium industry had not suffered the lethargy in which it has been immersed in the last thirty years, Venezuela would today have another pillar of the economy, which would give the nation greater slack in the strategic management of its oil industry.

- The events that took place during the 1990s and hindered the development programme designed and implemented by the Minister of State, Head of CORDIPLAN, Dr Miguel Rodríguez, unfortunately, prevented this plan from being undertaken.

- The abandonment suffered by our aluminum industry starting in 1993, coupled with the policy of destruction implemented during the beginning of this 21st century, and the paralysis of growth plans, have condemned thousands of Venezuelans to misery.

The year 1990 served for the successful start-up, commissioning, and performance of the Venezuelan Aluminium Reduction Technology, The V-350 Cell, designed by Venalum engineers, and whose purpose was the design of a CVG Venalum proprietary technology that would serve as a technology for new aluminium projects, both, for Venalum and for projects with international private investment in Venezuela, an initiative that was supported by the Minister of State and President of the Venezuelan Corporation of Guayana, CVG, Engineer Leopoldo Sucre Figarella.

- Venezuela has its own bauxite, gas, electricity, as well as its own development and design of aluminium reduction cell technology, The V-350 Cell, which was successfully tested in 1990, 10 years before any other successful design of high amperage cell in the world.

100% Venezuelan Reduction Technology. The V–350 Cell

The Design and Development of High-amperage Cell Technology for the reduction of aluminium carried out by the Research and Development Group of CVG Venalum, marked a milestone in the history of Science and Technology in Venezuela, and a milestone in aluminium reduction: first design worldwide for the year 1990 to successfully operate at amperage levels greater than 300 kiloamperes.

V-350 was the best high amperage cell technology above 300 kA between 1990 and 2000, before any other successful technology design from any country in the world.

As reported by Dr Alton Taberaux in the Journal of Metals, JOM, 52 (2) (2000), pp. 22-28, by the year 2000, the only cells operating at the maximum amperage level of 320 kiloamps in the aluminium industry worldwide were:

- The V-350 Cell, CVG Venalum, Puerto Ordaz, Venezuela, and

- The P-320 Cell, Pingguo, China.

“Venalum in Puerto Ordaz, Venezuela, developed five side-by-side V-350 point-fed PB cells, four side risers, with 36 anodes operating at 320 kA on their development line.”

Prebake Cell Technology: A Global Review

https://www.tms.org/pubs/journals/JOM/0002/Tabereaux-0002.html

VIDEO THE V-350 ALUMINIUM REDUCTION CELL

https://www.youtube.com/watch?v=wOn9QU1kVpk

- The aluminium sector in Venezuela has high-level human resources to support an efficient aluminium industry for the management and direction of the companies, as well as for the projects that make up the National Aluminium Plan that leads to a flourishing integrated industry, so there are no doubts of its high potential to accompany the oil industry in supporting the national economy.

VENEZUELA HAS HIGH LEVEL HUMAN RESOURCES TO SUPPORT AN EFFICIENT ALUMINIUM INDUSTRY

The technical, operational, and managerial group led Bauxilum in 2005 to the historical production record of 1,950,000 tons of alumina that year. And led Venalum, to produce at its installed capacity of 430,000 tons per year until 2008, when the power supply to the plant was cut off.

Since the 1990s, at CVG Venalum Research and Development Centre, and at CINTAL, the Aluminium Technological Innovation Centre, our group has worked hard to defend the potential of aluminium as one of the best options to accompany oil and other productive and service sectors, as a support for the Venezuelan economy, and the generation of wealth and well-being.

Currently, in contrast to international pressures regarding the use of clean energy in industrial processes, more than 70% of the primary aluminium produced in the world is made using electricity generated by fossil fuels.

Green aluminium is that produced through the use of electrical energy generated by renewable sources. The availability of hydroelectric energy for the production of green aluminium has become very important, due to international pressures and agreements to mitigate climate change, which requires a drastic reduction in the carbon footprint and imposes heavy sanctions on aluminium produced with electricity generated from fossil fuels.

These realities have motivated the large aluminium-consuming companies to seek important supplies of green aluminium, one of the most in need of these actions being the automotive industry, which has increased its consumption of aluminium due to the orientation of its markets towards electric vehicles.

Sales of electric vehicles

Another industry that is rapidly trying to secure supply of green aluminium is packaging, since part of its campaign to replace materials such as plastic, is based precisely on the better performance of aluminium in the fight against climate change.

These needs of the aluminium-using industries, in turn, have forced the primary aluminium producing companies to formulate and implement rapid strategies to ensure, in the short and medium-term, the maximum supply of green aluminium as possible.

Additionally, the possibility of fines and taxes, to be applied to aluminium produced using electricity generated from fossil fuels, is another factor of concern for aluminium producers, especially for projects to expand production capacity or construction of new plants, which must be economically efficient in order to cover the financial burden necessary for the execution of their projects.

New projects in the primary aluminium industry must use clean energy. Venezuela has enough hydroelectric potential for the efficient and competitive production of green aluminium. Additionally, Venezuela also enjoys climatic conditions that favour an extraordinary potential for the generation of wind and solar energy.

Similarly, Venezuela has vast reserves of bauxite for alumina production, making it a strong candidate to be one of the largest integrated producers of green aluminium.

Likewise, from CINTAL, aluminium has been promoted not only as an economic activity, but as an engine of territorial development, and CINTAL designed the Conceptual Engineering of two Aluminium Cities, located respectively in Caicara del Orinoco and El Palmar.

https://www.metalesymetalurgia.com/texto-diario/mostrar/3732169/enero-2007-arrancara-ciudad-aluminio

Given his career and successful experiences as a Researcher, Academician, Head of Industrial Operations, Manager, CEO, and President of large companies, as well as an internationally recognized Specialist and Advisor, Dr Jesus Imery is the high-level specialist to lead very assertively in the areas of Industry, Technology, and Innovation, in the Comprehensive and Harmonic Planning of Venezuela, especially in the Planning of the National Aluminium Sector.

https://www.linkedin.com/pulse/venezuela-green-aluminum-production-dr-jesus-alberto-imery-buiza/

No comments:

Post a Comment