VISIONARIES OF GUAYANA. MINERAL RESOURCES

IRON AND BAUXITE

INTRODUCTION

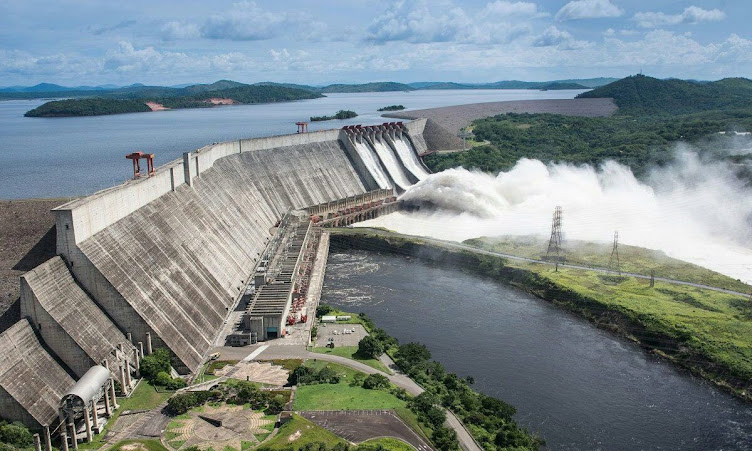

In the first part of this

title, a brief comment was made on what has been the emblematic work of

Venezuela throughout its history, as mentioned, the Strategic Planning conceived by the

VISIONARIES OF GUAYANA and reflected in the Caroní River Electrification

Project, platform for all urban, commercial and industrial development in the

Guayana Region.

As support and complement

to the National Electric System, consisting of a series of Thermoelectric

Plants located in the rest of the territory, the interconnection with part of the

rest of the country was installed through high voltage lines. Support and

complement of the National Electric System, which for the year 2000 would mean

the use of the Thermoelectric and the Hydroelectric Plants in a process of

alternating supply balance depending on the season or periods of drought and /

or rain, that is, during the descent or ascent of the levels of the dams.

For the year 2000, the

total electricity supply capacity of Venezuela was designed and made up of 40%

of the supply capacity from thermoelectric plants, and 60% from hydroelectric

plants. Thermoelectric generation has always had a sufficient design capacity

to supply energy to the country's demand in dry years. As the design of hydroelectric generation

depends on rain, there is always a guaranteed minimum value in dry years (firm

power).

During the dry season,

the hydroelectric plants would work at a lower intensity, being compensated

with a greater use of the capacity of the thermoelectric plants, and vice

versa, in times of rain when high levels of water are generated in the dams,

there would be available the energy reserves of hydroelectric plants. In this

way, an uninterrupted electrical service was guaranteed forever for the entire

country.

MINERAL RESOURCES OF THE GUAYANA REGION

The Guayana Region is a

land of enormous deposits of different metallic and non-metallic minerals.

Among the most abundant mineral resources in the Guayana Region are iron,

bauxite, gold, manganese, titanium, granite, coltan, and diamond.

Thanks to the great

positive impact on the economic and social development of the Guayana Region

and the entire country, the greatest emphasis on the use of mineral resources

has been directed for several decades, to iron, for the production of steel, and

to bauxite , for the production of alumina (aluminum oxide), and from this, for

the production of aluminium.

IRON

CVG

Ferrominera Orinoco C.A. arises as a consequence of the nationalization of the iron

ore industry. The two North American companies that were responsible in

Venezuela for the exploitation and commercialization of iron ore in the Guayana

deposits since the late 1940s were:

• Iron Mines Company of

Venezuela

• Orinoco Mining Company

The initial activities began with the exploitation of the

mineral from Cerro El Pao, located east of the Caroní River, 50 km from Puerto

Ordaz. In 1974 the iron industry was nationalized, and the agreement between

the Venezuelan Corporation of Guayana (CVG) and the companies Iron Mines

Company and Orinoco Mining Company, and their parent companies, was approved.

In 1975, the Venezuelan State, through the CVG, assumed

direct control and exercised the right of full ownership of the Iron Industry,

as well as complete freedom of decision and management to direct the Industry.

In this same year, CVG signed the articles of incorporation of CVG Ferrominera

Orinoco C.A. before the Commercial Registry.

Located in the vicinity of Ciudad Piar, south of Bolívar

State, Cerro Bolívar and Cerro Altamira deposits were the first two to be

exploited. Later, Cerro Redondo, Cerro Los Barrancos and Cerro Las Pailas among

others of smaller size, thus forming what is called the San Isidro Ferriferous Quadrilateral.

The San Isidro mine began operations in 1985, and at the

same time Ferrominera was advancing plans to support the mining development of Los

Pijiguaos (Bauxite), the rescue of the Minorca Plant and its supply with

mineral from the company, and Construction of the Iron Ore Transfer System to

increase export capacity and conquer new markets.

CVG Ferrominera Orinoco C.A. As an iron ore exploiter

and processor, it has a current installed capacity of 24 MM t / year. This is

generated in:

Mines (Extraction and Processing of ore): 24 MM t /

year

Pellas Plant (Pre-reduced): 2.5 MM t / year

Briquettes Plant (Steelworks): 1.5 MM t / year

Currently under construction is a Second Pellas Line

of 2.5 MM t / year and a Quartzite Concentration Plant to process 12 MM t /

year and produce 8 MM t / year.

With proven reserves of 4,200 million tons (MM t), the

company carries out its own transport of ore between the mines and the

production centers, and at the same time between them and the docks through a

system of railways and ships. Additionally, it has an open water Transfer

Station at the mouth of the Orinoco River with a storage capacity of 180,000 t,

which allows it to carry out movements of more than 6 MM t / year.

BAUXITE

The Guayana Shield is very fertile in mineral

deposits, among these large tracts of bauxite can be found, one of them being

commercially exploited in the Cedeño Municipality of Bolívar State,

specifically in Los Pijiguaos area where CVG Bauxilum operates a mine that it

has a current installed capacity of the order of six million tons per year.

In 1985, the CVG Ferrominera Orinoco (FMO) company,

with the intervention of its teams of geologists and mining engineers, designed

and established the initial exploitation plan for the CVG Bauxiven company, as

a technical contribution between companies of the same CVG group.

On March 24, 1994, CVG Bauxiven and CVG Interalumina

merged, the mine, and the refinery for the production of alumina, to give way

to the company we know today: CVG Bauxilum.

Bauxite is extracted at Los Pijiguaos mine, to be later

transported, processed, and converted into alumina at the Puerto Ordaz Plant. A

portion of the alumina produced is destined for the local market, the main clients

being the smelters CVG Alcasa and CVG Venalum, additionally, there are also

smaller clients such as companies producing abrasives, ceramic industries,

water purification plants, among others. The rest of the alumina not consumed

domestically is exported, with CVG Bauxilum having its own port facilities for

such purposes.

In addition to the bauxite deposits already

commercially exploited in Los Pijiguaos, preliminary studies have shown the

existence of various bauxite deposits in the Guayana Shield. The analyzes

carried out indicate that the inferred resources in granitic rocks could reach

2,621 MMt in the entire Guayana region, with alumina percentages of up to 52%,

and specifically it is considered that the inferred resources of the El Palmar

area are of the order of the 475 million tons.

In 2009, in work carried out by Universidad de

Oriente, Núcleo Bolívar, the potential areas in inferred bauxite resources were

evaluated in the old “Río Grande I Concession”, in El Palmar deposits. In this

way, the inferred resources are 475,000,000 tons for a depth of 4 meters and

270,000,000 tons for a depth of 2 meters. For both cases, the tonnage was

increased, if compared to the CVG Tecmin report of 1989, where the inferred

resources were initially established at 150,000,000 tons.

All the information on the history, mineral resources

and exploitation methods of the bauxite mine of Los Pijiguaos is available in

the document prepared by the Geologist Engineer and Mining Technology

Specialist, Noel Mariño, at the link:

NOEL MARIÑO: TECNOLOGÍA MINERA

Under the management of Engineer Noel Mariño as

General Manager of Operations, it was possible to achieve in 2006, the highest

production level in the history of the Bauxite mine in Los Pijiguaos, with a

production of 5,927,839 tons in crushing, and 5,764,053 tons in barge cargo.

El Palmar area is close to the Orinoco Delta, CVG

Bauxilum's alumina plant, as well as the gas development of the Delta Platform.

The commercial exploitation of El Palmar deposits offers the National Executive

options for attracting foreign investment, opening up to private capital,

generating jobs, economic reactivation, territorial deconcentration of highly

populated areas, and starting functions by executing projects of great impact

on the national economy. Investors can develop greenfield-type projects, both

in the industrial park and in the urban area.

As aluminium production in Venezuela has the advantage of

a bauxite mine and alumina plant, aluminium production does not incur costs for

freight, unloading, and handling of alumina, thus considerably reducing the

cost of production and therefore improving the profits. Additionally, the

country has sufficient hydroelectric infrastructure located in the same state

where the aluminium industrial park is located, so electricity costs are highly

competitive.

Additionally, and as explained by Dr. Jesús Imery in

his blog dedicated to Aluminium as a Development Engine of the Venezuelan

Economy:

POR QUE VENEZUELA DEBE POTENCIAR SU INDUSTRIA DEL ALUMINIO

1. The

Guayana Region has the energy and natural resources to be a power in the

production of iron, steel, aluminum, and the installation of an associated industrial

park.

2. Our

AlProTeS specialists have the technical and economic information, as well as

the execution schedules as required by companies and financial and investment

institutions, interested in projects for the recovery, diversification and

growth of the iron and aluminum industry In Venezuela.